What is Abrasive Blasting?

Abrasive blasting is a pressurized process that propels media against a surface. Abrasive blasting is often known to as sandblasting* or grit blasting. The blasting process creates a high-powered stream of media using compressed air, a centrifugal wheel, or even water.

Benjamin Chew Tilghman patented the first artificial sand blasting system in 1870. This system was intended to recreate the eroding effects that occur in nature. Erosion takes place when dirt, sand, and other mineral particles are blown by harsh winds. Tilghman figured out how to turn that into a tool for manufacturing.

Common Applications for Abrasive Blasting:

- Clean a surface of rust, grease, or dirt

- Removal of paint or debris

- Create textures

- Create cosmetic surface finishes

- Removal of burrs, weld beads, or edge profiling

- Cleaning foundry casting or molds

- Prepare surfaces with an anchor pattern for paint, adhesive bonding, or other coatings

- Strengthen surfaces or relieve stress, also known as shot peening

- Peening the surface smooth for lubricants

- Engrave stone or etch glass

- Removal of flash

- Mold or fire restoration

- Preparation for thermal sprays

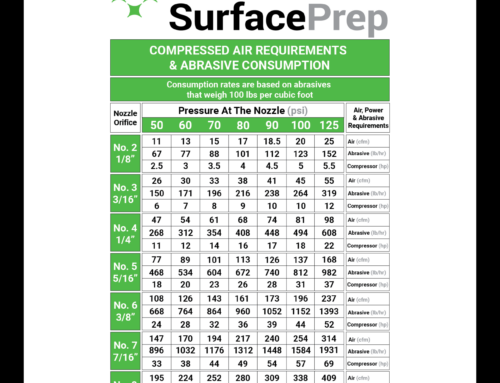

There is a wide range of blasting equipment options available on the market. They can be broken down into three main categories: air blasting, wheel blasting, and wet blasting. The type of equipment that you invest in will depend on the surface treatment goal as well as the end use of the piece being worked on. If you need to touch up products, a hand cabinet might be what you need. But if you are shot peening to reduce stress in an aerospace part, you will want an automated system to ensure consistency.

* Even though it is still often called “sandblasting”, sand is no longer used in abrasive blasting. Sand, or silica sand, is dangerous to workers’ health. NIOSH and the CDC warn that blasting with silica sand, which contains crystalline silica, can cause serious or fatal respiratory diseases. There are over a dozen safer and more productive blast media alternatives available. *