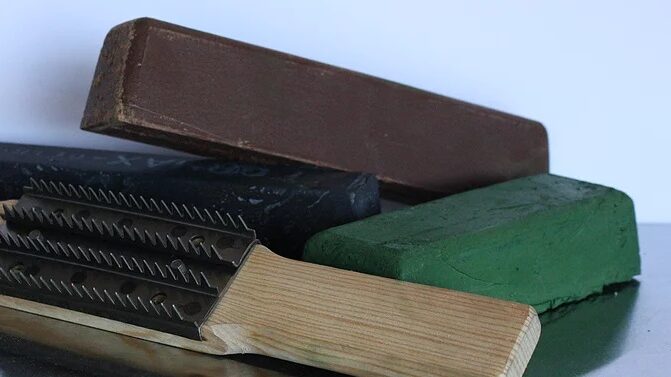

Compounds are available for buffing and polishing applications for various types of surface materials and stages within the surface finishing application.

Buffing operations can generally be divided into two operations: cutting down and coloring:

-

Cutting down is a preliminary step that uses a coarser grade buffing compound. In some cases, this process can yield an acceptable appearance.

-

Coloring is a lighter duty buffing intended to bring up the luster and polish the work surface. The coloring compounds use finer mesh abrasives to enhance and brighten the work piece.

Buffing wheels and compounds work together, either to carry the abrasives across the work surface to cut and color, or to generate sufficient frictional heat to impart a polished finish. Compounds are available in liquid and solid forms for use with buffing wheels. Grease-less compounds are available in grit ranges from 60 to 600.

The compounds are applied to a wheel and are designed to deburr, blend machine lines, and remove surface imperfections. Each compound is designed for specific alloys and plastics.

Note: Buffing is a low RPM operation. The wheel and compound generates enough heat to help “pop” the polish. Too high an RPM can prevent the luster and color, creating a surface haze, either from excessive heat and/or wheel frays that whip the work surface.