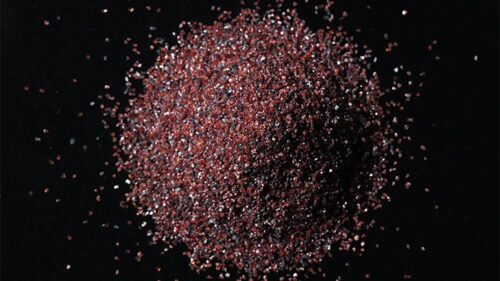

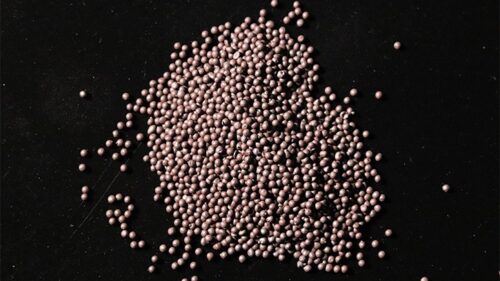

BLAST MEDIA

What is Blast Media?

Blast media can be defined as any abrasive that cleans, removes, finishes, or prepares a surface. The media is propelled with the use of compressed air or via centrifugal force by a bladed wheel. The media impacts the surface to be finished to erode any unwanted materials, to prepare a surface for a coating to be applied, or to provide a desired surface finish.

Blast media is often referred to, incorrectly, as “sandblasting media”. Silica sand should never be used in blasting processes. Learn more about the dangers of working or blasting with silica sand on OSHA’s website.

Which Abrasive is Best for Your Process?

SurfacePrep can assist you with your media selection process. Your specific application parameters, such as required finish, production output, and available processing time, are important factors when choosing the right abrasive blasting media. With around 46,000,000 lbs. of abrasives in our warehouses, we can supply you with the right product when you need it.

Characteristics of blast media can all determine the surface profile the abrasive creates. Those characteristics are bulk density, the shape of the abrasive, hardness, and the number of times the abrasive can effectively be recycled. Different types of abrasive blasting media have different characteristics, therefore, creating different surface profiles.

Benefits of Blasting:

- Efficiency – Abrasive blasting processes can reach areas of the workpiece, or surface, that can be hard to access by other surface finishing means.

- Eco-Friendliness – The process is more environmentally friendly since most blast media are natural materials and recyclable.

- Surface Profiling – The profiling of the surface is easily controlled by the use of different media types and sizes, opening up a wider range for customer application requirements.

- Operator Safety – The use of abrasive blasting media for cleaning poses less of a health risk than other cleaning techniques, but operators must take protective measures with proper PPE.

At SurfacePrep, your safety and satisfaction are our top priorities. We focus our efforts on providing world-class customer service and support, to insure we provide the best materials to our customers.

SurfacePrep stocks a large quantity of abrasive blasting media and abrasive finishing equipment that will meet your application needs. Our knowledgeable, friendly associates are ready to help you find the materials that fit your needs and provide solutions to your problems.

Contact us today to learn more, receive a quote or place an order!