One of the most common cutting tool processes is drilling. Drilling covers a wide range of cutting tools, such as:

- Drill Bits

- Step Drilling

- Center Drills

- Spot Drills

- Reaming

- Countersinking

- Boring Bars

SurfacePrep represents many major brands of Holemaking tools, such as Dormer-Pramet, Sandvik, and more. With a choice of HSS, HSS-E, and carbide substrates, geometries to suit general purpose hand-held to high performance CNC applications, and a diameter range from 0.006 inch (0.15mm) to over 4.0 inches (100mm), our drilling program represents a complete hole-making solution.

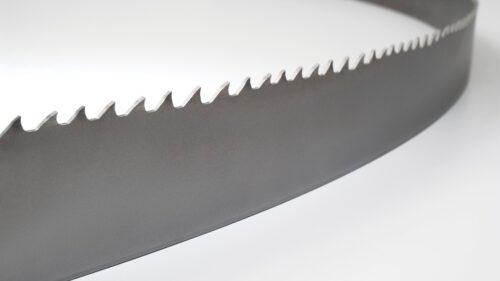

HSS Holemaking

High speed steel (HSS) drill bits offer the highest strength and stability in many applications and, for this reason, are the most popular style of drill. We offer a vast range to fit almost every machining method and material type. This includes different lengths, shank styles, surface finishes and geometries.

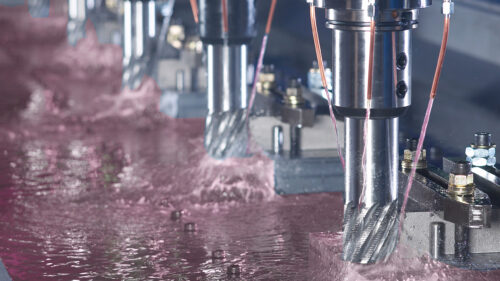

Solid Carbide Holemaking

Our range of solid carbide (HM) drills support maximum metal removal rates whilst maintaining high levels of accuracy – up to H8 hole tolerance. Capable of performing at accelerated cutting speeds, our program supports drilling depths up to 8xD, including solid and coolant fed variants with designs, geometries, and coatings to maximize cost-per-hole efficiencies.

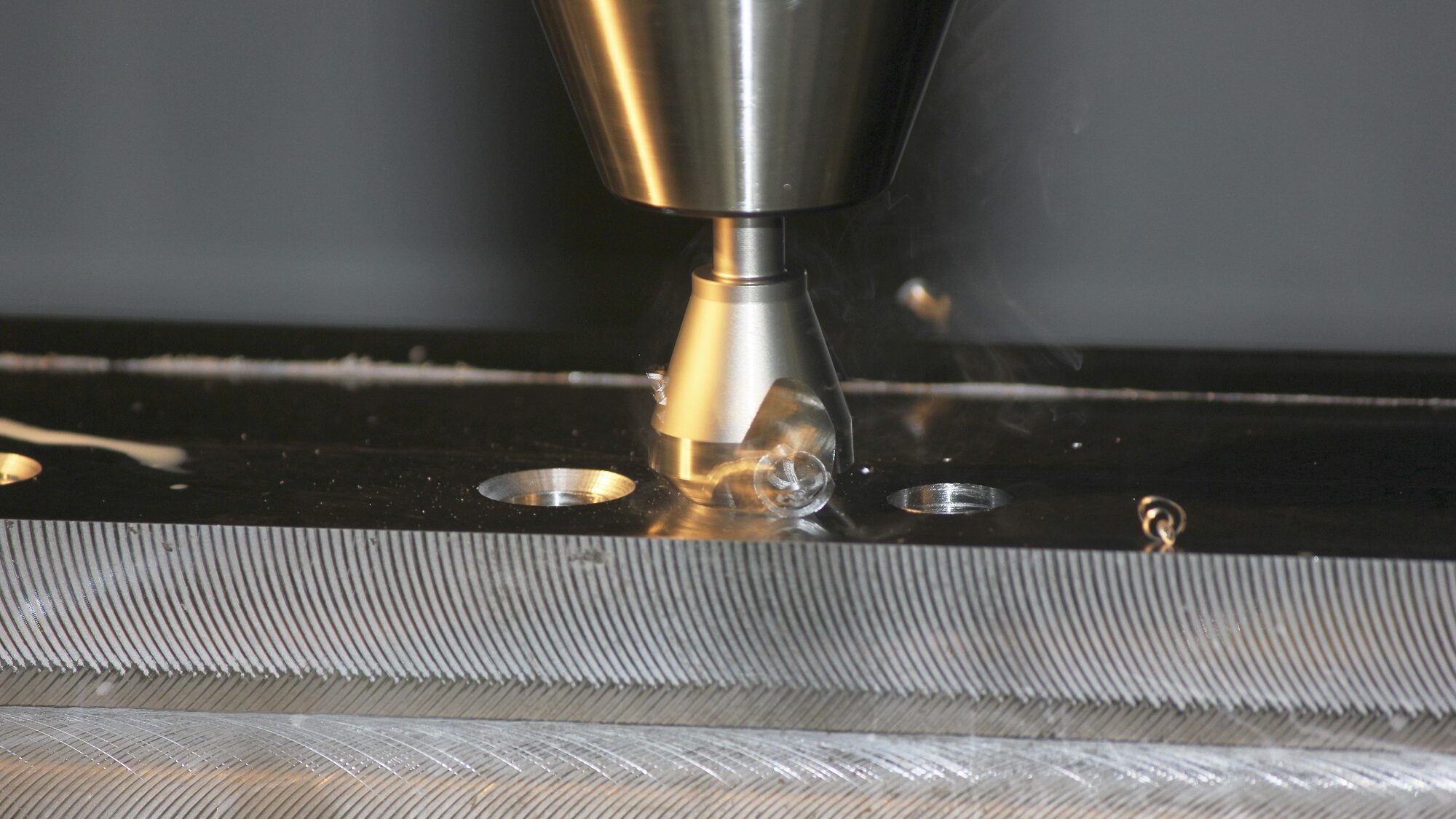

Indexable Holemaking

When larger holes – above 0.6 inch (15mm) diameter – are required, indexable drills represent the most efficient and economical solution. We offer carbide inserts with 4 cutting edges mounted to a tool steel drill body and the Hydra range of replaceable head drills. Both options provide an optimal mix of strength, performance, and economy.