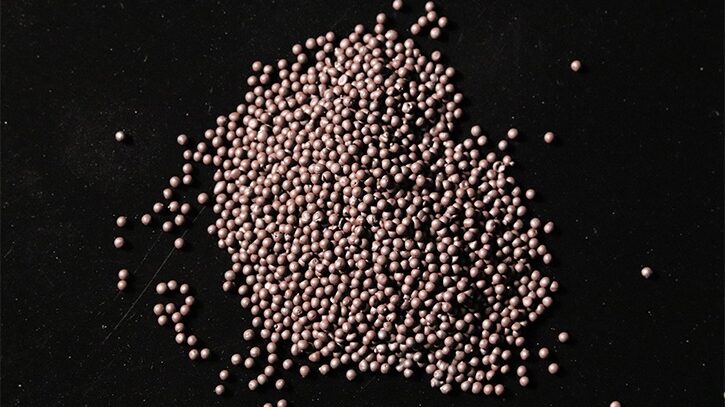

One of the most common metallic abrasives is steel shot. Steel shot can sometimes be confused as steel grit, but they are very different products.

Steel shot is spherical in shape. Steel shot will provide a smoother surface finish than steel grit.

Steel shot comes in a variety of sizes and levels of hardness. The bulk density is very high and must be taken into consideration with how that might affect your blasting equipment. Appropriate equipment needs to be implemented in order to properly use steel blasting media.

Processes using steel shot must be able to tolerate a level of ferrous residue on the workpiece. When steel breaks down, it will leave ferrous contamination on the parts being blasted. Because of its durability and low-attrition rate, steel shot is a popular choice in wheel blast equipment and properly outfitted blast rooms.

Steel shot is sized by screening. The sizing numbers for shot pertain to the actual size of the shot particulate, not a mesh size. The larger the number designation for steel shot the larger the size of shot. Low-carbon steel shot is available as well.

Steel Shot Abrasive Applications:

- Cleaning

- Peening steel and other hard surfaces

- Preparation of concrete

Steel Shot Characteristics:

- Spherical Shape

- Bulk Density – Approx. 300 lbs. per cubic foot

- Hardness Ranges:

- GP (40-51 HRC)

- GL (54-61 HRC)

- GH (> 60 HRC)

- Shot Size Range: S70 – S780