The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

Factors Affecting Media Flow

Several factors influence media flow in a blast cabinet. Understanding and

optimizing these factors is key to achieving the benefits outlined below.

Media Type and Size

Different blasting media have varying flow characteristics. Choosing the right

media for your specific application and regularly monitoring its condition can help

maintain proper flow.

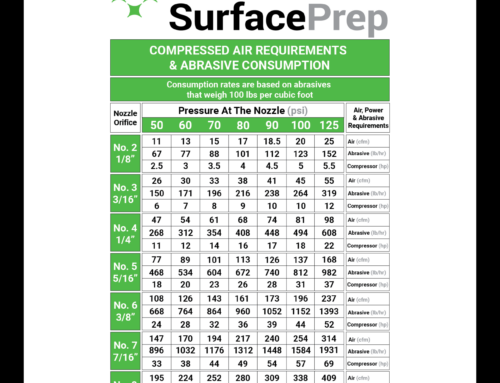

Air Pressure and Volume

Proper function of an abrasive blast cabinet is heavily dependent on the air

supply. It is imperative to maintain the efficiency of your compressor and air

filtration system to produce clean, dry air at the correct pressure and volume. This

will ensure a consistent flow of media during the blasting process.

Equipment Setup and Maintenance

Proper setup of your blast cabinet, including correct hose and nozzle sizing, as

well as the condition of your media reclamation and delivery system, can impact

flow. Regular maintenance helps prevent wear that can disrupt media flow.

Achieving Optimum Media Flow

Optimum abrasive flow depends on many factors as noted above. The key is to

use as little abrasive as possible while maintaining the maximum cleaning rate.

The air-abrasive mixture should be mainly air. As a rule, the stream of abrasive

coming out of the nozzle should barely discolor the air when seen against a

contrasting background. Properly adjusting the media flow helps achieve:

Improved Operational Efficiency

Efficient media flow reduces turbulence in the blast hose and minimizes the time

required to achieve the desired surface finish. This boosts productivity and allows

for faster turnaround times. Moreover, it reduces the amount of abrasive media

needed for each job, leading to cost savings and a more sustainable operation.

Consistent Surface Finish

Proper media flow ensures that the abrasive particles are distributed evenly

across the surface, leading to a uniform finish. This consistency is crucial for

applications where precision and appearance are essential, such as in

automotive, aerospace, and manufacturing industries.

Better Operator Visibility

Proper media flow contributes to effective dust collection within the blast cabinet.

By optimizing the media flow, this ensures that dust and fine particles are

efficiently captured and removed, creating a safer and cleaner working

environment. This is especially important for maintaining compliance with health

and safety regulations

Conclusion

At SurfacePrep, we are committed to helping our

customers achieve the best possible results in their

abrasive blasting operations. By emphasizing the

importance of proper media flow, we aim to

enhance the efficiency, quality, and longevity of

your equipment and processes. Whether you are

setting up a new blast cabinet or optimizing an

existing one, understanding and controlling media

flow is a critical step toward success.

For more information on how SurfacePrep can

support your surface preparation needs, contact us

today. Our team of experts is ready to assist you in

selecting the right equipment, media, and

maintenance strategies to ensure your blasting

operations run smoothly and efficiently.

About SurfacePrep

SurfacePrep is a leading distributor of abrasive

finishing equipment, offering a wide range of

products and services to meet the needs of various

industries. With a commitment to quality,

innovation, and customer satisfaction, we provide

solutions that enhance surface preparation

processes and deliver exceptional results.