Transform your Operations with Equipment and Processes you can trust

Air blasting is a critical step in the finishing process that uses compressed air to propel abrasive media against a work surface for various applications, including rust and scale removal, anchor pattern creation, cosmetic finishing, coating removal, shot peening, cleaning, and restoration after mold or fire damage.

Key factors to consider when selecting the appropriate air blasting equipment include surface characteristics (size, shape, and area to be blasted), the material of the part, the coating being removed, and the type of abrasive media needed for desired results.

Depending on your specific project requirements, we offer solutions ranging from abrasive air blasting machines including portable blast systems to larger-scale blast rooms and cabinets for controlled, repeatable blasting operations. We also offer automated and robotic blast systems to improve operational efficiency.

Learn About Our Vendors

Why Choose Our Air Blast Equipment?

Abrasive Air Blast Equipment & Dust Collection Systems

SurfacePrep partners with trusted OEM Manufacturers to supply a full range of air blasting equipment, including Clemco, Empire Abrasive Equipment, Axxiom Manufacturing, GVS-RPB, Bullard, and more!

Typical Applications

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

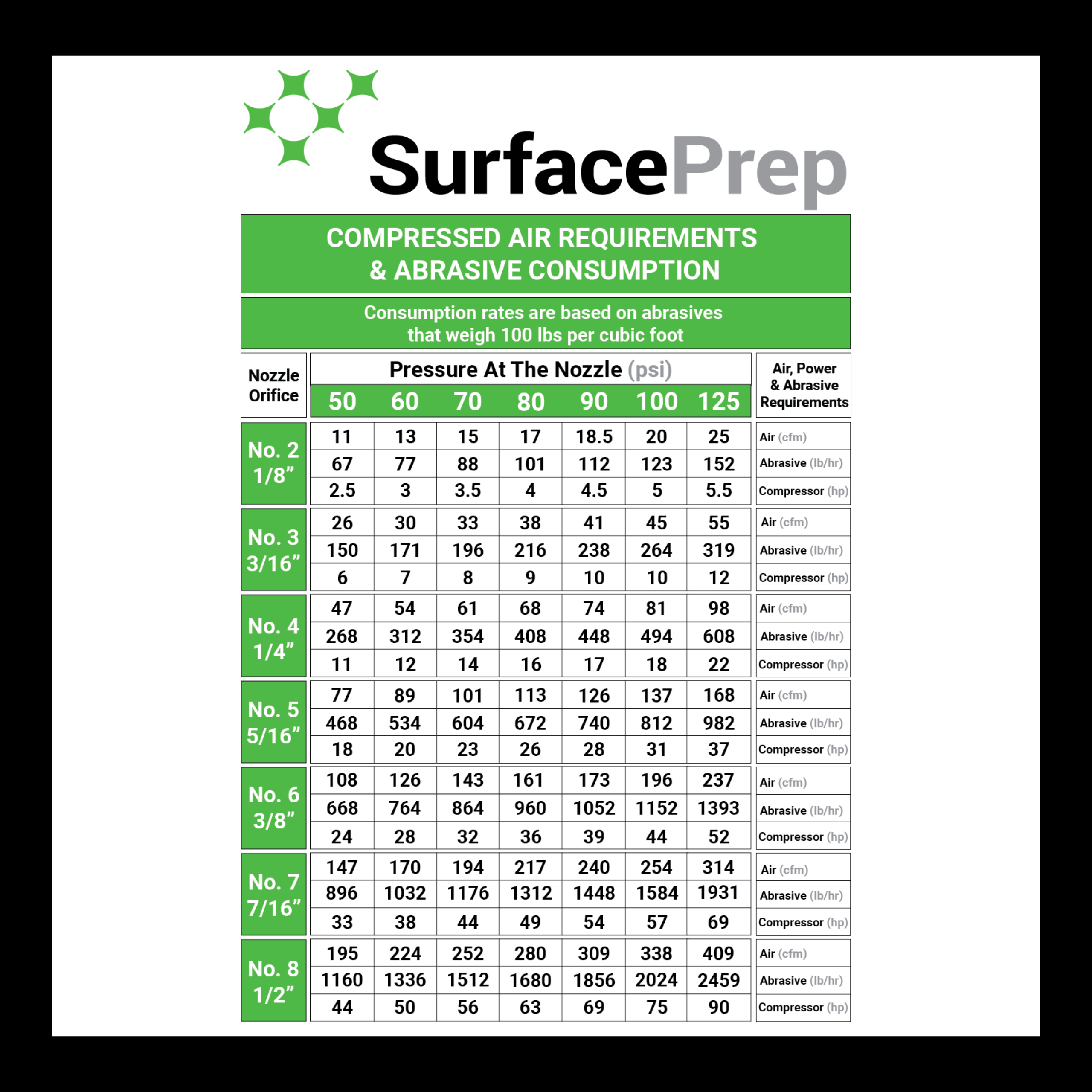

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.