Chemistry plays a large role in manufacturing processes, from cleaning to providing decorative finishes to corrosion protection. A lot of the chemistries used every day have undergone many transformations over the years, to comply with federal, state, and local regulations without changing their effectiveness.

SurfacePrep represents many major brands of chemistry and compounds for surface preparation cleaning, deburring, degreasing, paint stripping, and more.

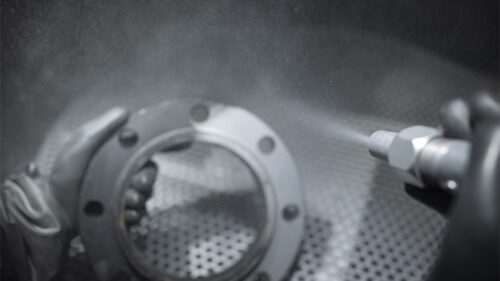

VIBRATORY COMPOUNDS

Vibratory Compounds are designed to work with vibratory media to make the process more efficient and productive. There are many options to choose from for vibratory compounds. Choosing the correct one depends mostly on the alloys of the parts and the objective of the process. There are compounds specifically designed for ferrous, non-ferrous, and multi-metal applications.

Vibratory compounds provide a combination of performance components including:

- Cleaning is one of the primary functions of vibratory compounds. Proper compound selection will clean and emulsify the oils or coolants from the parts, then remove it from the process channel. Compound is also critical by keeping the media clean and prevents glazing. Glazed media loses its cutting ability, which will increase processing time.

- Deburring is a function whereby compound removes residue or contaminants on the work piece and allows the media to cut more efficiently. Deburring compound allows media to slide over the part, removing burrs. Without deburring compound, the media mass would not work as effectively.

- Burnishing compound is utilized to brighten the appearance of the parts being processed. The enhanced appearance can be accomplished with many types of vibratory media however porcelain as well as steel media are typically used. Burnishing compounds add color and luster to the parts as they are processed.

- Inhibiting properties will help prevent corrosion during the vibratory process. Typically, the concentration level of inhibitors is too low to provide any protection after the process is completed. With ferrous metals, other steps to dry the parts or apply higher concentrations of corrosion protection will need to be implemented to avoid further rusting post-process.

AQUEOUS-BASED CLEANERS

Aqueous-based cleaners are most like detergents. They create sudsy pockets that help lift and remove contaminants and greases. Aqueous-based cleaners are designed to enhance the cleaning ability of water. They typically contain a surface-active agent that not only helps eliminate soils by dissolving contaminants, but they also chemically react with those pollutants to help them become more dissolvable in water. Many aqueous cleaners have options that add in detergents, emulsifiers, inhibitors, anti-foaming agents, PH buffers, builders, deflocculants, and chelating agents to help clean different levels of soil and different types of substrates.

SOLVENT-BASED CLEANERS

Solvent-based cleaners rely on the chemicals within the solvent to help dissolve the surface contaminants. Solvents remove thick, baked on oils, greases, dirt, and more. The ability to tweak and modify the chemicals in solvents lends to being able to create very specific cleaning chemistries for removing specific soils from parts and surfaces. Some cleaners are even capable of removing a specific ink type on a plastic substrate while leaving the rest untouched.

CORROSION PROTECTION

Corrosion protection is available in a variety of thicknesses and finishes to meet a variety of requirements. These protectants range from dry-to-touch, ultra-thin, transparent coatings up to glossy, wax finishes. Corrosion protectors are available in oil, solvent, wash, acrylic, and aqueous-based formulations. Your product specifications or process, such as salt spray test, will determine which corrosion protection is needed. Rust is costly, either resulting in rework or scrapping of parts. Protect your products and your investments.

COOLANTS & LUBRICANTS

Coolants and lubricants typically work together in the metalworking industry, like machining, milling, and stamping. Coolants and lubricants are also commonly referred to as cutting fluid or cutting oil. The goal of coolants and lubricants are to help reduce heat caused by friction, maximize the life of the cutting tip, and to help prevent rust on the machine parts or cutters. There are many different types of cutting fluids, such as oils, oil-water emulsions, pastes, gels, mists, or dry form.

WELD CLEANING

Weld cleaning solutions on stainless steel show a fast ROI compared to the labor required to mechanically remove discoloration. They are fast and easy, using non-hazardous chemistry that does not alter the surface finish.

PAINT & POWDER COATING STRIPPERS

Paint and powder coating strippers have proven to be safe, effective, and economical. They are a great option when compared to a burn-off oven, to rework parts, or to remove build-up on caps, plugs, and hooks. Non-hazardous ferrous and non-ferrous formulations work best when heated and agitated.

BUFFING COMPOUNDS

Compounds, in liquid or solid form, are available for buffing and polishing applications for various types of surface materials and stages within the surface finishing application.

Other chemistries that are also available: black oxides (conversion coatings), antiquing, paint-prep, phosphates, adhesive removers, and bright dips.

SurfacePrep can help you decide which type of chemical solutions would be best in your equipment and process. To request an order for chemicals and compounds, please click the button below or call us at 888-873-1066.