GIBSON SH1244 SPINNER HANGER WHEEL BLASTER

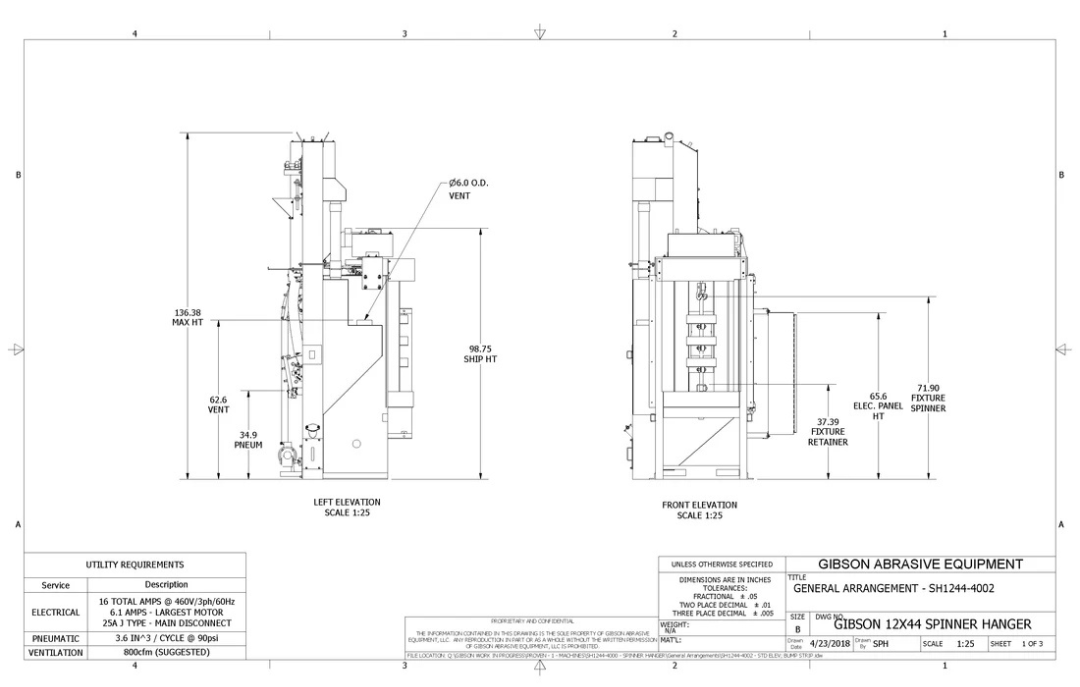

CABINET

Fully welded

Fabricated from 1/4” steel plate

3/8” thick Manganese Back Wall

Pressure-Sensitive Chamber Rotation Safety Guard

Perforated Screen, ¼” dia. holes

Access door in rear of cabinet permits removal of tramp metal collected on abrasive screen

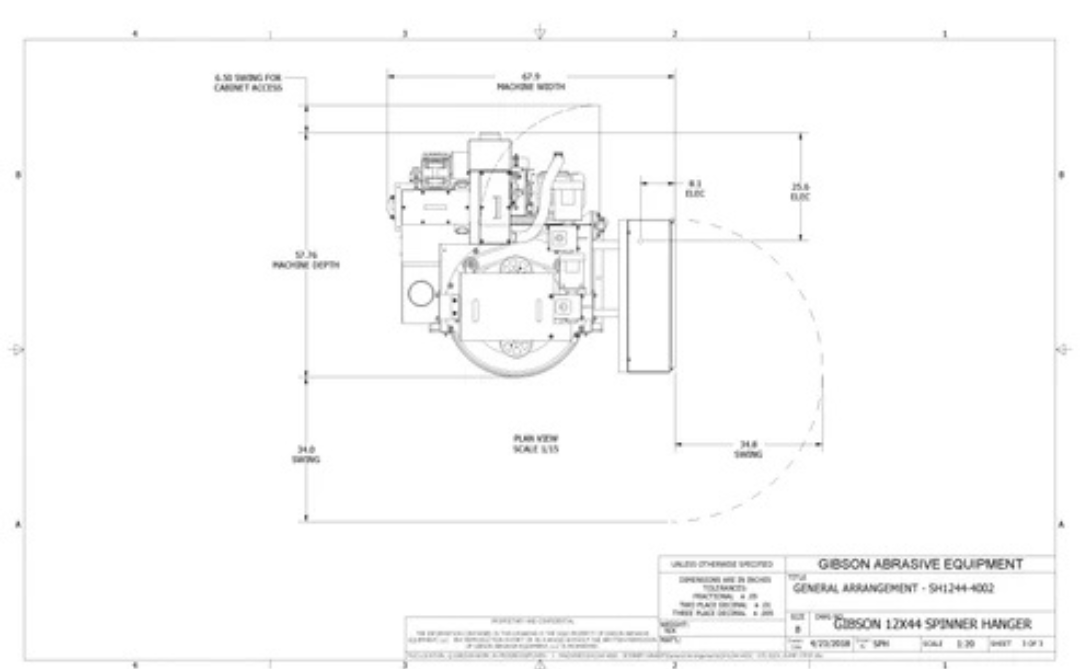

DUAL CHAMBER

Chamber rotates on 2” dia. shaft with heavy-duty thrust bearing

¼” thick Manganese Plates in Blast Area

Hook Spindle provided in each chamber

Pulley-Driven

HOOK SPINDLE

¼” thick Manganese

250 lb. capacity

15 rpm

12” dia. x 36” Maximum Blast Envelope

12” dia. x 24” Optimal Blast Envelope for top-to-bottom coverage

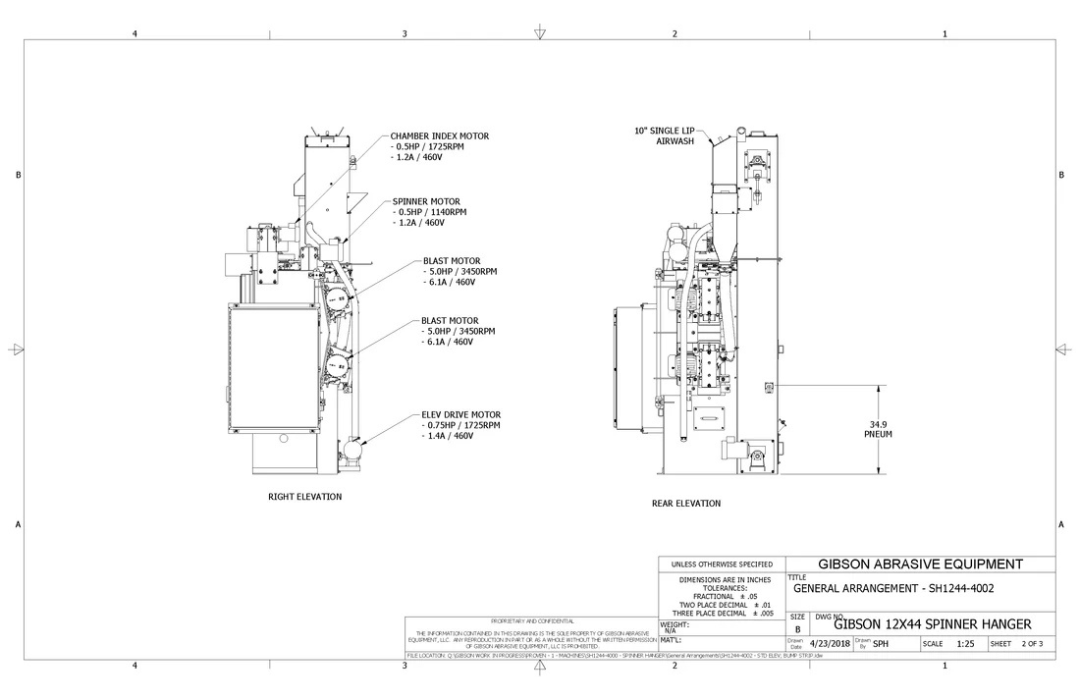

WHEELS

(2) 10” diameter Wheels

Direct drive, 3,510 rpm, 5 hp

Four (4) 2” wide Curved Blades

Balanced for smooth operation

HUB

Patented technology allows wheel assembly to be dynamically balanced. This allows for increased motor life, major sound reduction, and less downtime.

BLADES

Snaplock design eases blade replacement

Curved blades provide maximum abrasive control

Cast from abrasive resistant alloy

CONTROL CAGE

Dial Type, eases blast pattern adjustability

WHEEL HOUSING

1/4” thick Steel Plate

Alloy Steel Lined, Replaceable

ELEVATOR

V-Belt Bucket Elevator with positive tracking, easily adjustable

Heavy-Duty C-Section Elevator Belt

Multiple-Cord Construction

Solid Cast Iron Elevator Sheaves

3” Metal Stamped Buckets

Hopper Debris Screen

10” Single Lip Airwash Separator

ABRASIVE CONTROL VALVE

Totally enclosed butterfly valve

Air Cylinder-Operated

Fully Adjustable

VENTILATION

Requires 800 cfm at 6” static pressure

**Ducting from system to dust collector is not included.**

**We Have Dust Collectors For Sale That Will Work Well For This Unit.**

ELECTRICAL CONTROLS

NEMA-12 Panel (380/50/3) with 480V Auto Transformer

Low Level Sensor in the Hopper to Monitor Media Levels

End of Cycle Delay Timer prior to chamber index

Automatic Cycle Staging Capability

‘Blast On’ Hour Meter

Motor starter for 2 hp Dust Collector