Spray & Dispense Equipment

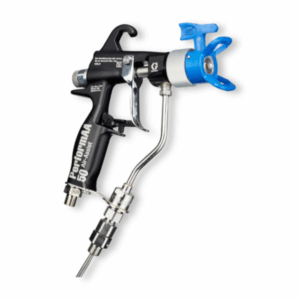

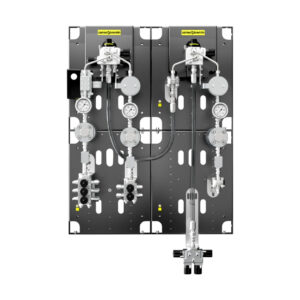

Spray and dispense equipment is used to apply materials onto various substrates and is essential in many industries for tasks such as coating, sealing, bonding, or finishing. Because each application and material is unique, solutions must be tailored to factors like material properties, part complexity, production demands, finish requirements, safety, and budget.

SurfacePrep partners with trusted spray equipment OEM Manufacturers to supply a full range of spray & dispense systems. Let us help you overcome the confusion and find the right solution for your finishing requirements.

Some of our OEM Partners Include:

Why Choose Our Spray & Dispense Equipment?

Industry Articles

How to Use a Paint Spray Gun – Complete Guide

How to Use a Paint Spray Gun A Complete Guide