Surface Preparation Standards: SSPC/NACE

The joint surface preparation standards by NACE International and the Society for Protective Coatings (SSPC), which have recently united to form The Association for Materials Protection and Performance (AAMP), are widely accepted among contractors and organizations.

While these standards provide an effective framework for achieving consistent surface preparation results, they can be confusing due to their numbering system, which does not necessarily indicate higher levels of surface preparation with higher numbers. To aid comprehension, the following is a simplified breakdown of each standard.

SSPC-Surface Preparation (SP)-1: Solvent Cleaning

This standard for surface preparation is meant to remove soluble substances from steel. Before a paint or other protective coating is applied, a solvent is used to remove all visible oil, grease, dirt, drawing or cutting compounds, or other soluble contaminants. Solvents may include steam, emulsifying agents, or other cleaning compounds.

SSPC-SP-2: Hand Tool Cleaning

This manual cleaning standard aims to remove all loose contaminants from a steel surface using non-powered handheld tools.

SSPC-SP-3: Power Tool Cleaning

Similar to hand tool cleaning, this standard uses power tools to remove loose contaminants from the steel surfaces.

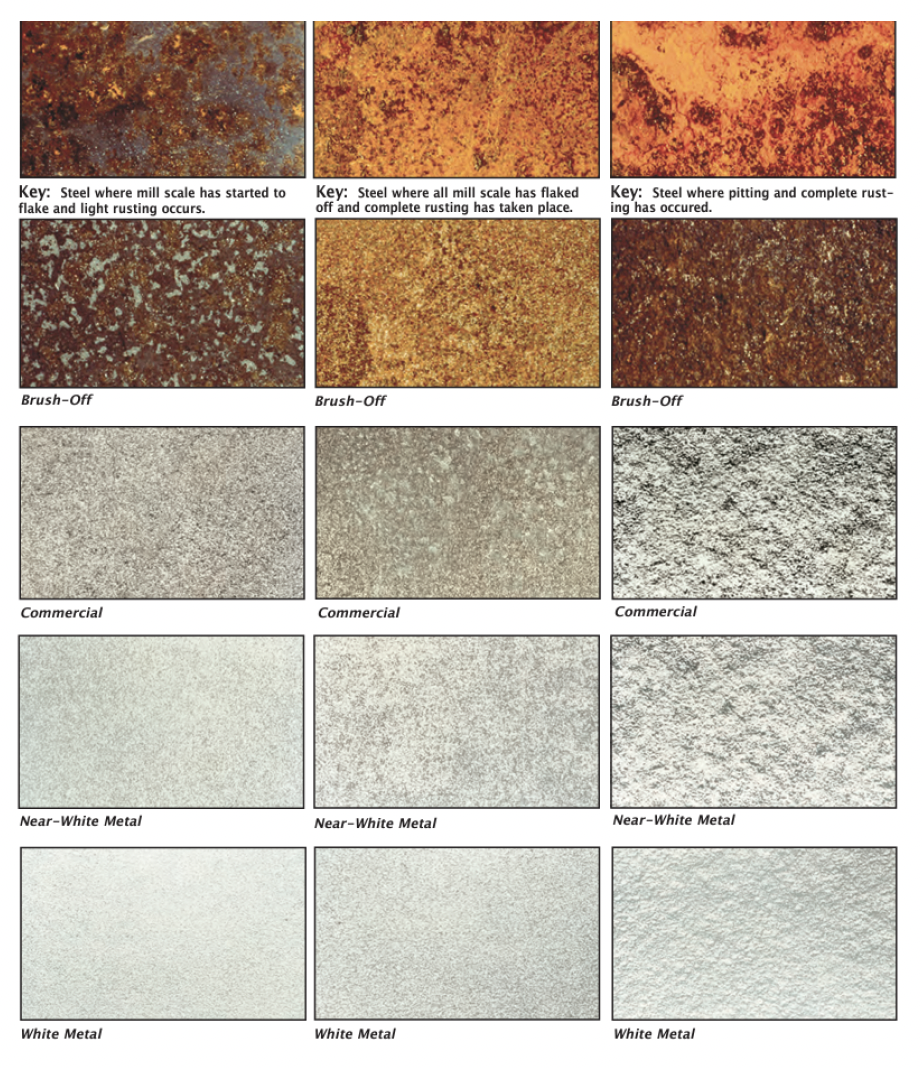

NACE No. 1/SSPC-SP-5: White Metal Blast Cleaning

This standard involves blasting a steel surface with abrasive media until it achieves a uniform white or gray appearance, free of all foreign matter. Per SSPC, a white metal-blasted surface should be visibly clean of all contaminants without magnification.

NACE No. 3/SSPC-SP-6: Commercial Blast Cleaning

This standard includes pre/post-blast cleaning instructions. It states that surfaces prepared to a No. 3/SP-6 standard, like white metal blast cleaning, should be visibly free of contaminants. Random stains from previous exposure are acceptable if they cover less than 33% of any unit area. These stains may appear as light shadows, streaks, or discolorations.

NACE No. 4/SSPC-SP-7: Brush-Off Blast Cleaning

This standard states all oil, grease, dirt, and dust must be cleared from the surface when viewed without magnification. Loose mill scale, rust, and coatings must also be removed, but tightly adherent mill scale, rust, and coatings may remain.

NACE No. 2/SSPC-SP-10: Near-White Metal Blast Cleaning

This standard states all oil, grease, dirt, and dust must be cleared from the surface when viewed without magnification, except for a limited amount of acceptable staining. Unlike with a commercial blast, only 5% of each area unit, as defined by the standard, may exhibit staining. This 5% may consist of light shadows, slight streaks minor discolorations that could be the result of exposure to rust, mill scale, or of a previous coating.

SSPC-SP-11: Power Tool Cleaning to Bare Metal

This technique involves bringing a surface down to bare metal, creating or preserving a minimum surface profile of 1 mil (25.4 microns) This surface does not allow for stains from mil scale, rust, or paint to remain on the surface.

NACE No. 8/SSPC-SP-14: Industrial Blast Cleaning

Like commercial blast cleaning, this standard cleans steel surfaces with abrasive media, permitting minimal staining. Unlike other standards, this allows for surface stains, tightly adhering mill scale, rust, and coatings on 10% of each unit area.

SSPC-SP-15: Commercial Grade Power Tool Cleaning

This standard, like SSPC-SP-11, involves stripping a surface to bare metal, but unlikeSP-11, it allows for some staining to remain.

SSPC-SP-16: Brush Off Blast Cleaning of Nonferrous Metals

This standard involves preparing non-ferrous metal surfaces for coating, requiring a minimum surface profile of .75 mil (19.0microns).

In Conclusion:

It is crucial for all coating contractors to correctly prepare the surface, whether the project involves coating a bridge, lining a steel tank, or protecting a water tower. Therefore, understanding and appropriately using these standards is invaluable.