Abrasive Blast Media Supplier

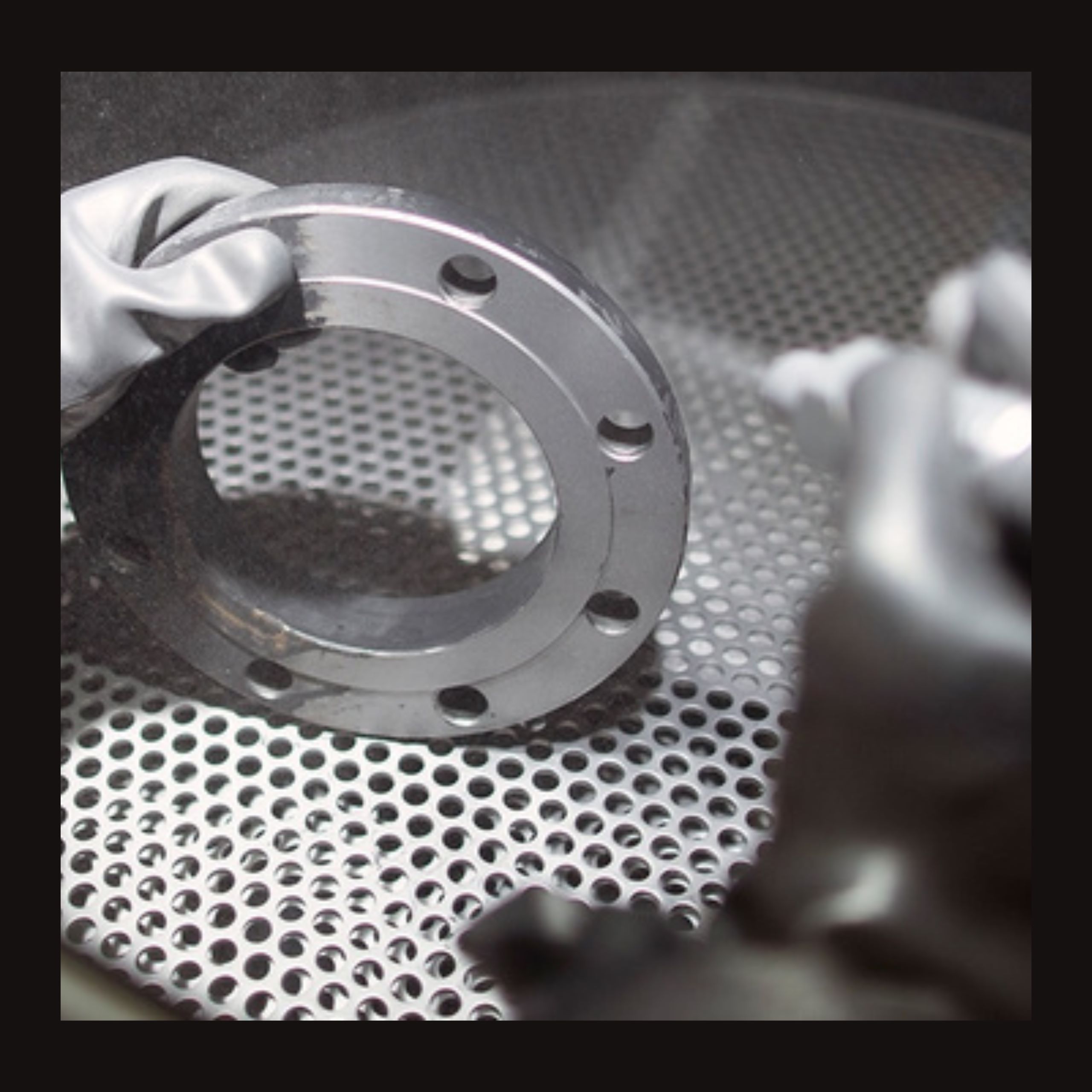

SurfacePrep is a leading supplier of abrasive blasting media for industrial surface preparation. Blast media consists of abrasive particles propelled by compressed air or centrifugal force to clean, strip, or finish a surface. From removing rust, scale, and coatings to creating the exact surface profile for optimal coating adhesion, our high-quality blast media delivers consistent, reliable results.

With a nationwide network, extensive in-stock inventory, and technical experts, we provide fast delivery and guidance to ensure you have the right abrasive blasting media for your application. We work with you to select the ideal abrasive type, size, and hardness to improve efficiency, reduce costs, and extend equipment life.

Often referred to as “sandblasting media,” blast media should never include silica sand due to the serious health risks of respirable crystalline silica. Learn more about silica hazards on OSHA’s website.

Choose SurfacePrep as your trusted blast media partner — delivering the products, expertise, and support to keep your operations running at peak performance.

Learn About Our Vendors

Choose the Right Abrasive Blast Media

Particle Size

Particle size, measured in mesh or microns, dictates the impact intensity and surface finish. Larger particles deliver a more aggressive impact, ideal for heavy rust, scale removal, or creating a rough surface profile for coatings. Smaller particles, on the other hand, are gentler and produce a smoother finish, perfect for delicate cleaning or surface preparation for painting.

Particle Hardness

Particle hardness, often referred to as strength or durability, influences the media’s ability to withstand the impact of blasting and resist fracturing. Stronger media can be reused multiple times, making it a more economical choice for large projects. However, the substrate material also plays a role. A very hard abrasive might be too aggressive for a softer substrate.

Particle Shape

The shape of the abrasive particle significantly impacts the blasting process and the resulting surface profile. Different shapes offer varying degrees of cutting action and create distinct surface textures.

Benefits of Abrasive Blasting

Abrasive Air Blast Media Products

At SurfacePrep, your safety and satisfaction are our top priorities. We focus our efforts on providing world-class customer service and support, to ensure we provide the best materials to our customers.

SurfacePrep stocks a large quantity of abrasive blasting media and abrasive finishing equipment that will meet your application needs. Our knowledgeable, friendly associates are ready to help you find the materials that fit your needs and provide solutions to your problems.

Contact us today to learn more, receive a quote, or place an order!

Frequently Asked Questions

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

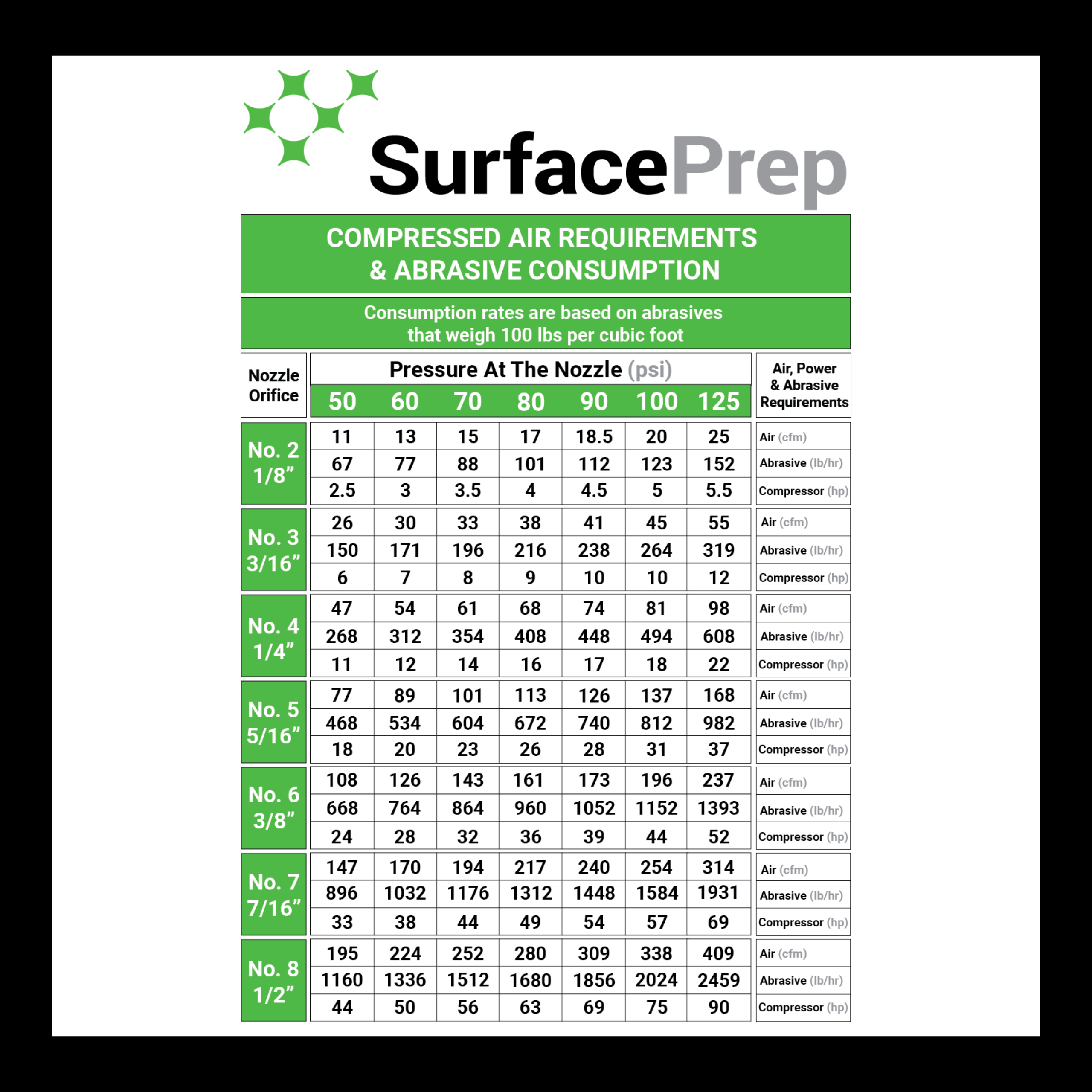

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.