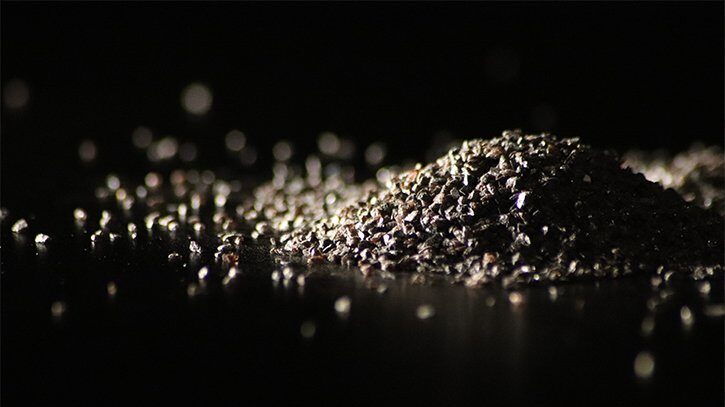

Aluminum oxide is fused in an electric arc furnace which produces a high-strength, tough, and extremely durable grain. Aluminum oxide is useful in many forms. The most common form is brown fused. Brown fused aluminum oxide is a general-purpose, loose grain abrasive that is used in abrasive blasting, polishing, lapping, or other finishing applications. SurfacePrep also supplies white fused aluminum oxide for applications that need minimal foreign contaminant.

When blast equipment is paired with a media recovery system, aluminum oxide offers multiple turns/recyclability before it breaks down. Typically propelled by air, aluminum oxide acts as a powerful, multi-edged abrasive that will penetrate the work piece while creating an exceptionally clean and uniquely etched surface. This unique surface finish is excellent preparation for an application of paint or powder coating via anchor pattern creation.

Aluminum oxide can be used on a variety of materials such as ferrous metal, steel, many metal alloys, stainless steel, glass, ceramic, marble, granite, stone, and other hard surfaces.

Brown Aluminum Oxide Abrasive Applications:

- Abrasive blasting

- Polishing

- Lapping

- Cleaning of investment castings

- Anchor pattern creation for coating or bonding applications

- Surface preparation for thermal spray coatings

- Stone and granite monument lettering

- Glass etching or frosting

- Matte surface finishing

- Anti-skid surfaces

- Paint, coating, scale, rust, or contaminate removal

Physical characteristics:

- Sharp, angular shape

- Hardness is around 9 on the Mohs scale

- Due to hardness and durability, aluminum oxide is generally reusable for multiple turns with the proper abrasive reclamation equipment

- Chemically inert

- High-melting point

- Medium to high bulk density

- Available in macro and micro grit sizes to reach a wide variety of application needs