Depowdering

Finishing Systems, You Can Trust

Additive Manufacturing is making waves throughout various industries. By reducing cost and lead times, 3D printed parts are in high demand. After printing these parts aren’t usable without proper finishing techniques, that’s where SurfacePrep comes in. Through our partnership with AMT we are able to provide our customers with high quality depowdering equipment tailored to fit their specific application taking into account material and particle size.

AMT’s depowdering equipment employs programmable robotic agitiation, vibration, and directed airflow to remove residual powder from additive manufacturing builds regardless of complexity. Production ready depowdering equipment is designed for easy expansion from pilot cells to fully automated production lines. These enclosed systems meet ATEX and NFPA standards for explosive powder environments, while integrated dust collection ensures OSHA and HSE compliance for operator safety.

Speak to a SurfacePrep specialist today to learn about solutions for your specific application!

PostProDP Pro

PostProDP Studio

PostProDP

PostProDPX

PostProDP Max

Why Choose Our Depowdering Equipment?

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

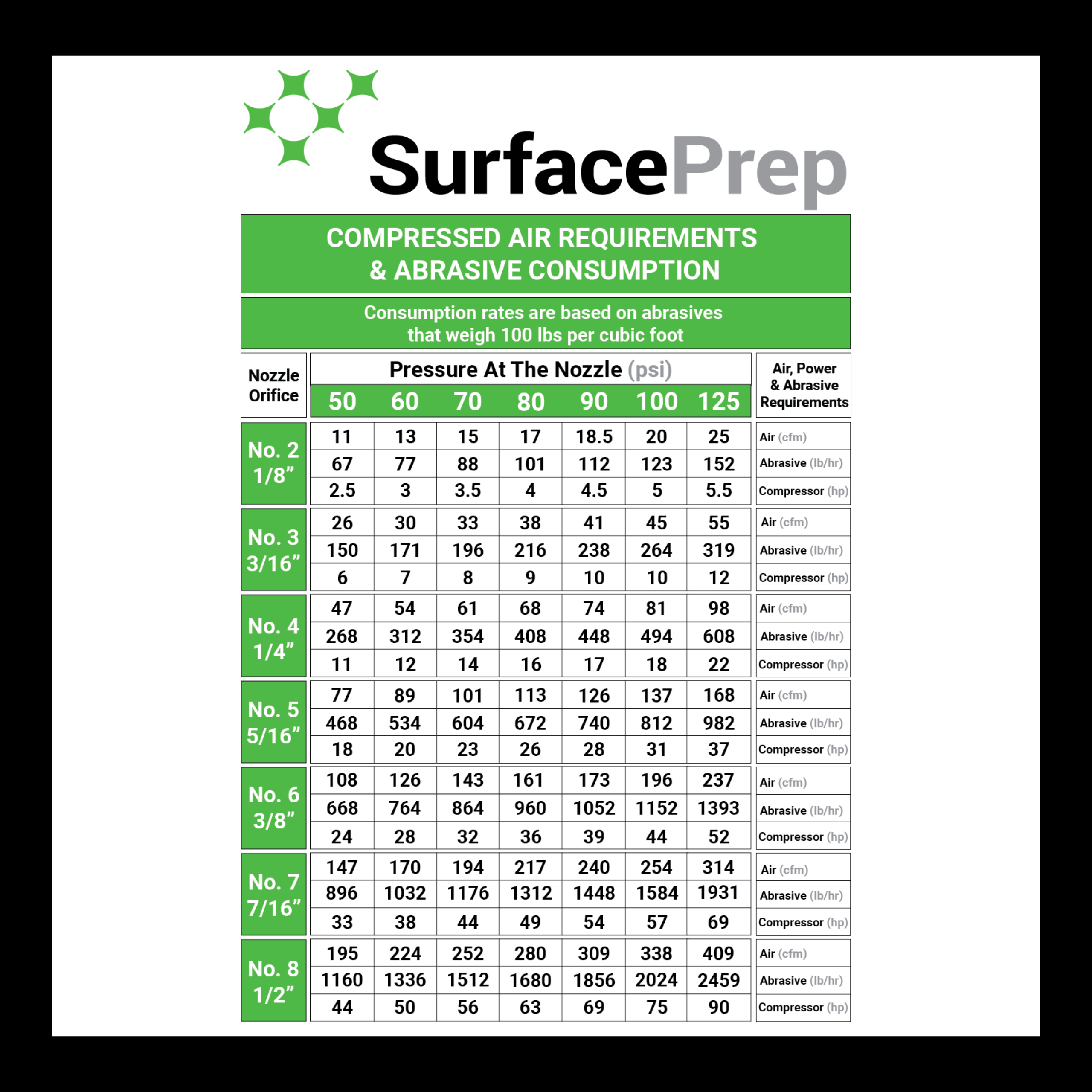

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.