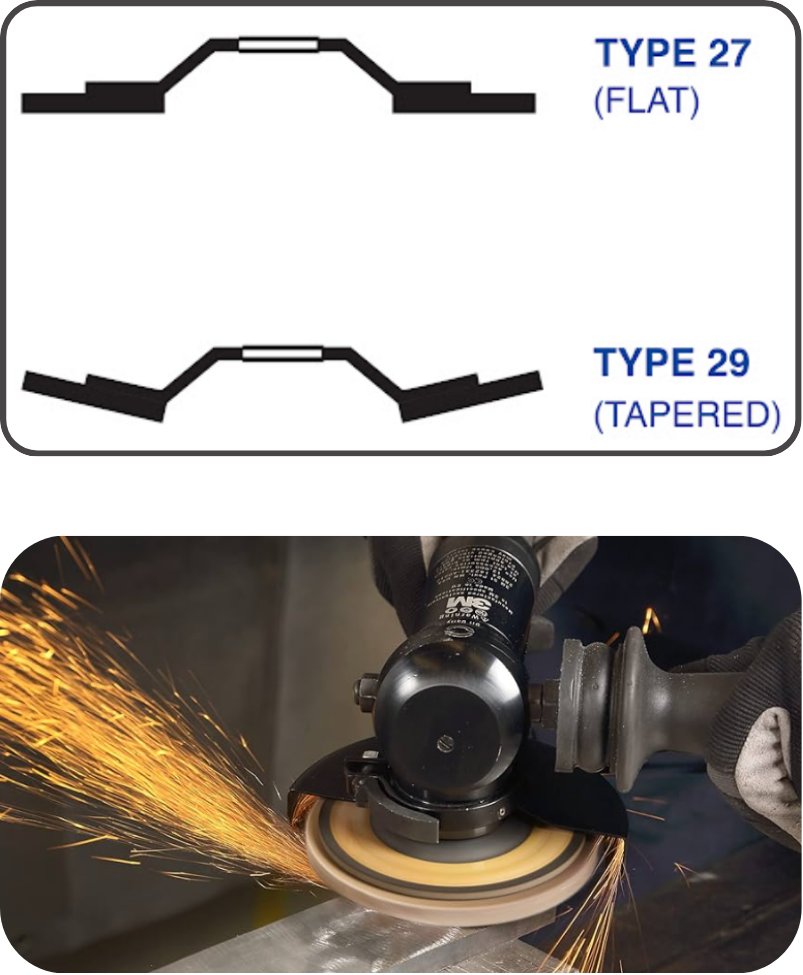

Flap Discs: The Differences Between Type 27 and Type 29

Overview

Flap discs are indispensable in commercial metalworking, offering a versatile and efficient alternative to traditional grinding wheels. Designed for use with angle grinders, these discs feature coated abrasive flaps for dual-action grinding and finishing. The unique construction of flap discs, available in various grit sizes and materials, ensures durability and a contoured finish. Notably, Type 27 and Type 29 flap discs are engineered for specific applications, providing solutions for a range of professional grinding needs with distinct design advantages.

Type 27 Flap Discs

Designed with a flat profile for use at 0-15° angles, Type 27 flap discs excel in smooth finishing on flat surfaces. These discs are ideal for operations that require refined finishing and blending, though they’re not intended for aggressive material removal or contour work.

Pros:

- Superior for smooth finishing and blending.

- Optimal for use on flat surfaces.

Cons:

- Not suitable for aggressive material removal or contour work.

Type 29 Flap Discs

Type 29 flap discs feature a conical shape with an angled surface, perfect for 15-25° work angles. This design allows for efficient contouring, shaping, and aggressive material removal, making them versatile for both edge work and stock removal on flat surfaces. The angled approach offers greater surface contact for more aggressive grinding.

Pros:

- Ideal for contouring, shaping, and aggressive stock removal.

- Facilitates effective grinding and blending in one operation.

Cons:

- Less effective for precision finishing and blending on flat surfaces.

Making the Choice

The selection between Type 27 and Type 29 flap discs should be guided by the specific demands of the commercial project at hand. Type 29 discs are favored for tasks involving contoured surfaces or when aggressive material removal is essential. Meanwhile, Type 27 discs are better suited for projects that demand precise finishing and blending on flat surfaces.

Conclusion

For commercial metalworking projects, the choice between Type 27 and Type 29 flap discs can significantly impact efficiency and quality. Understanding the unique benefits of each type allows professionals to tailor their approach to meet project specifications precisely, enhancing productivity and achieving optimal results in the industry.