Custom Industrial Blast Rooms Designed for Performance and Profitability

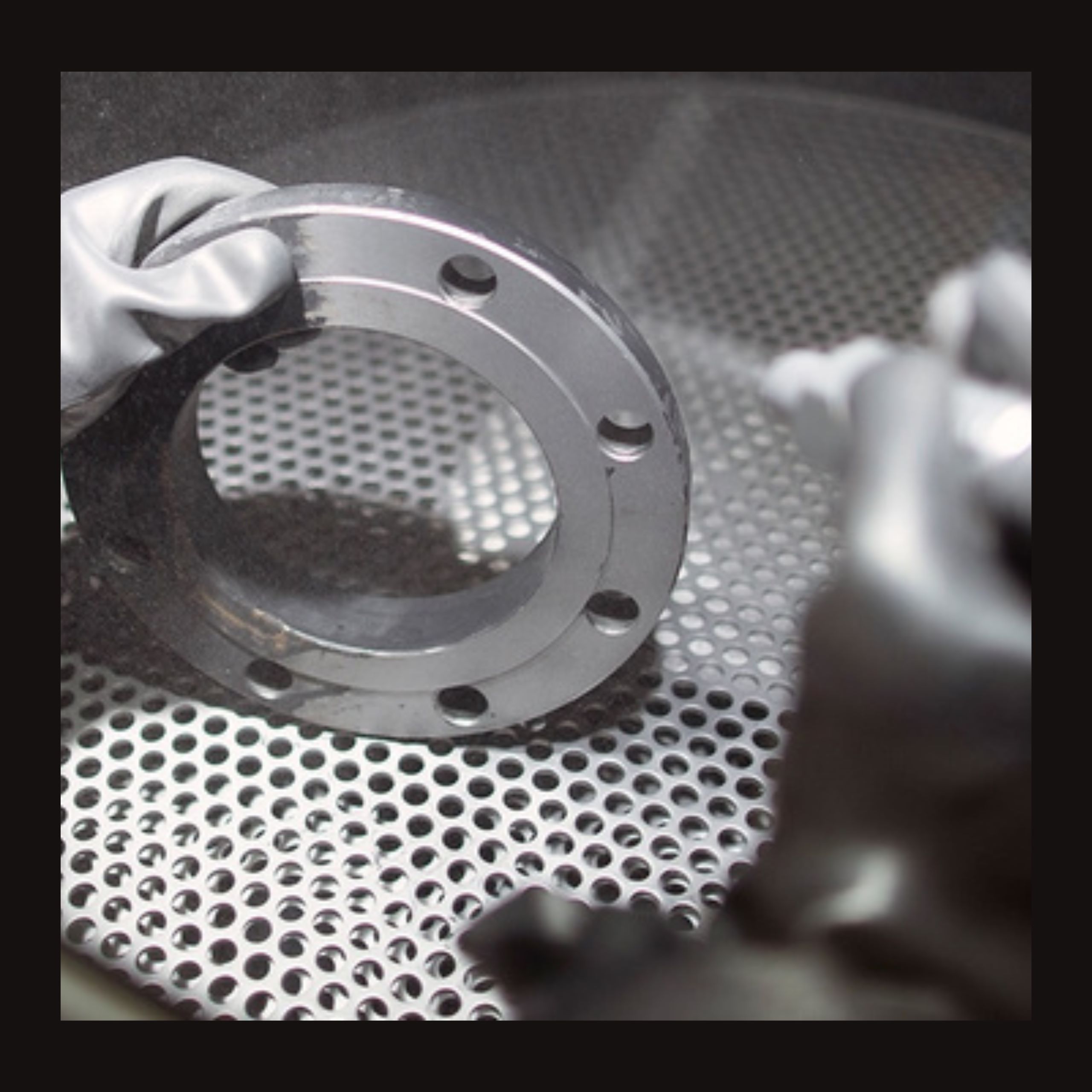

SurfacePrep partners with leading manufacturers to design and build custom blast room systems engineered for efficiency and performance. From abrasive selection to complete system integration—including the enclosure, recovery system, blast equipment, and dust collection—our air blast specialists ensure your solution is built for maximum efficiency, safety, and ROI. Whether you need a new blast room design, an upgrade, or a complete system integration, SurfacePrep provides a reliable solution backed by proven industry expertise.

With decades of experience and a broad network of facilities, SurfacePrep delivers turnkey blast room solutions that enhance product quality, consistency, and throughput across industries such as aerospace, transportation, energy, and general manufacturing.

Our blast room systems include:

- Blast Room Enclosures – Flange bolt, column bolt, and field-erected designs for any part size or facility layout.

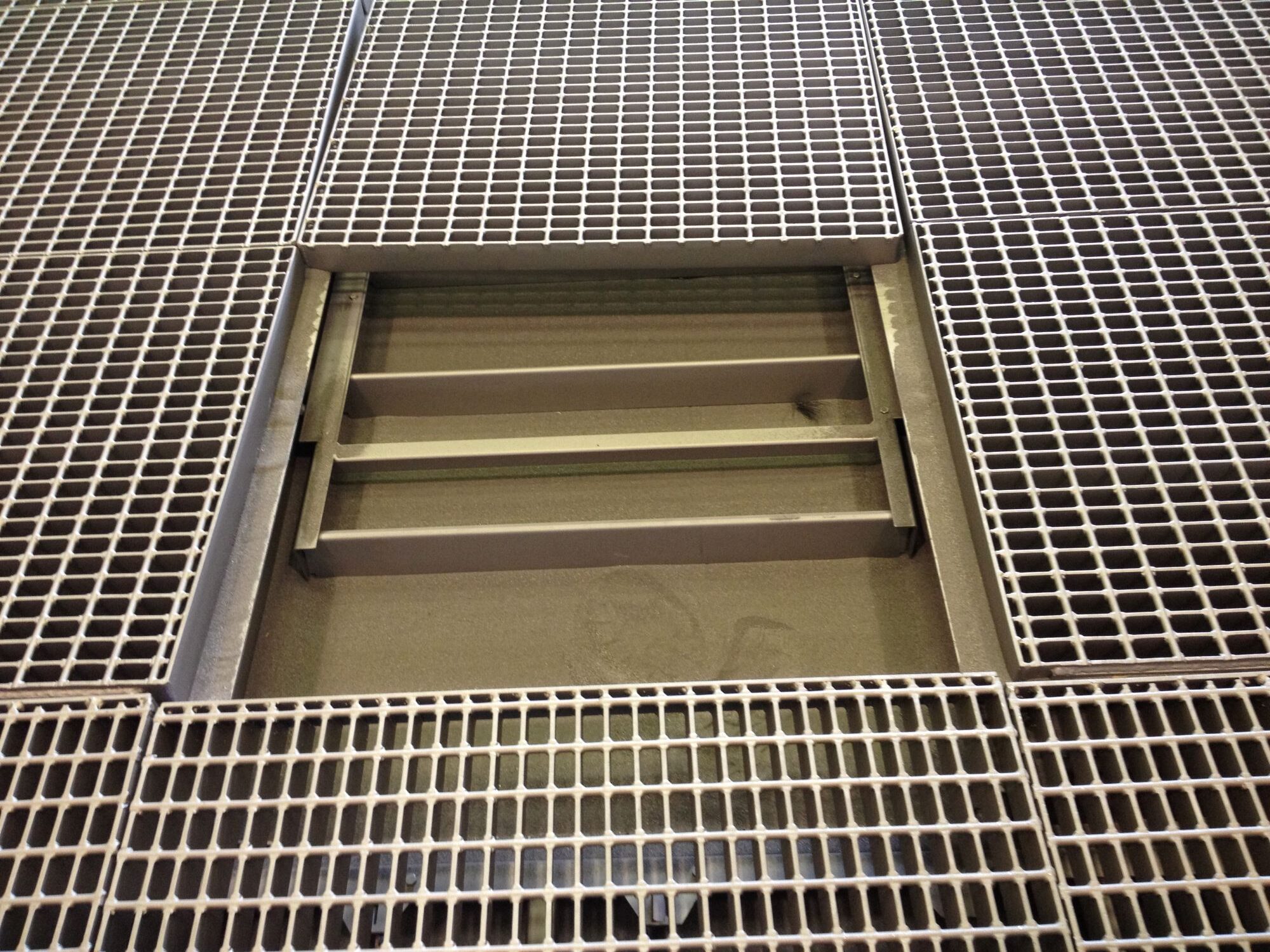

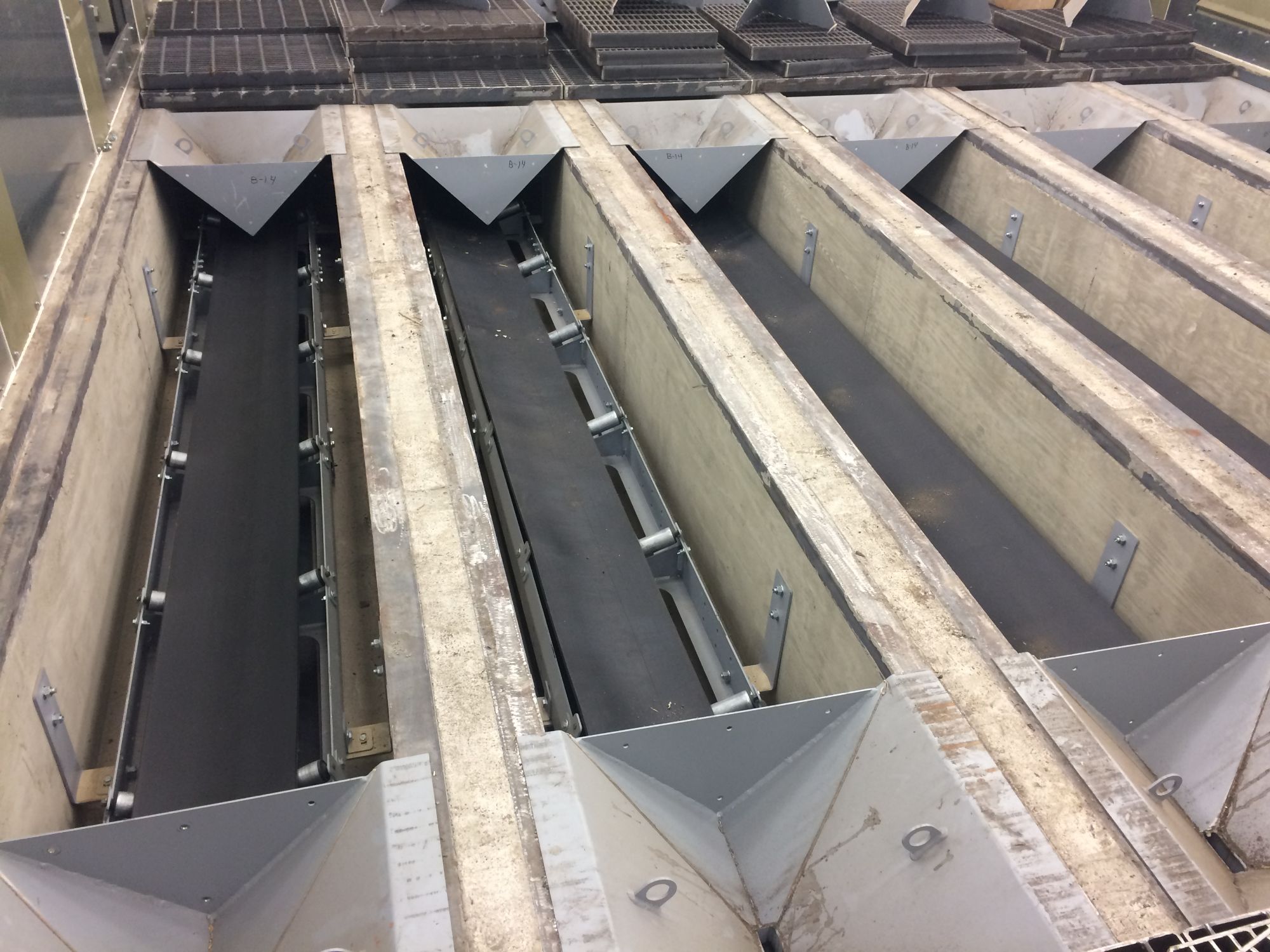

- Floor Recovery Systems – Sweep-in, auger, belt conveyor, and pneumatic recovery options to reduce labor and media waste.

- Abrasive Cleaning Equipment – Mechanical and pneumatic systems for media recycling and dust separation.

- Dust Collection Systems – Modular collectors with optional HEPA filters, explosion vents, and and rotary air locks to meet air permitting and NFPA regulatory compliance.

- Blasting Systems – Single or multi-operator blast machines with low-pressure options for delicate surfaces.

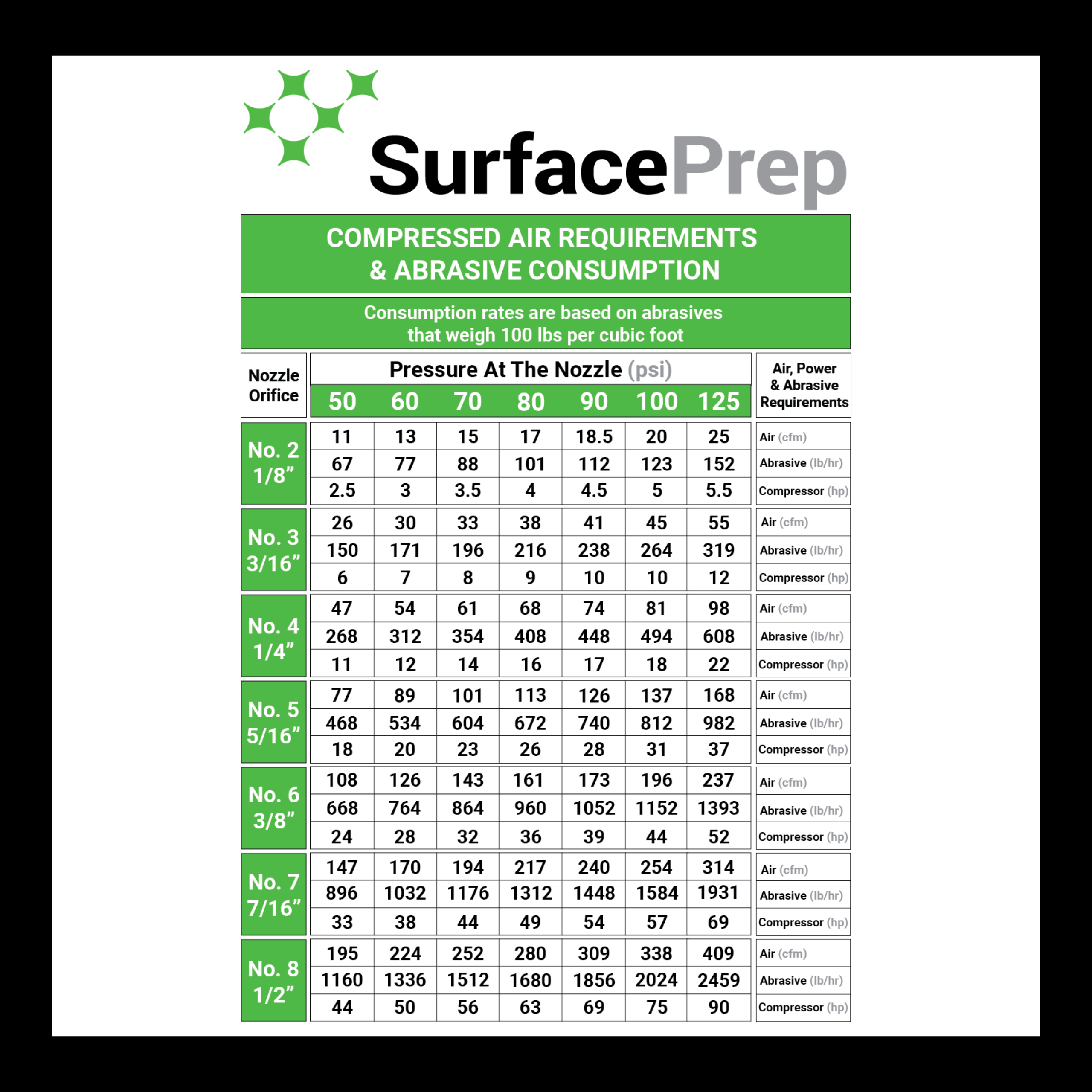

- Compressed Air Supply – Sized to meet your CFM requirements and media type.

- Electrical Controls – NEMA-rated panels with PLC automation and maintenance tracking.

- Work-Piece Handling – Turntables, monorails, catwalks, and overhead cranes for safe and efficient part movement.

- Start-Up & Training – On-site setup, troubleshooting, and safety training to ensure long-term success.

Why Choose SurfacePrep?

- One-source liability for complete system integration

- In-house abrasives and paint equipment supply

- Maintenance audit services and 24/7 support

- Proven ROI through recycled media systems and optimized layouts

Applications

Blast Room Media Recovery Systems

Blast Room Options

Industries Served

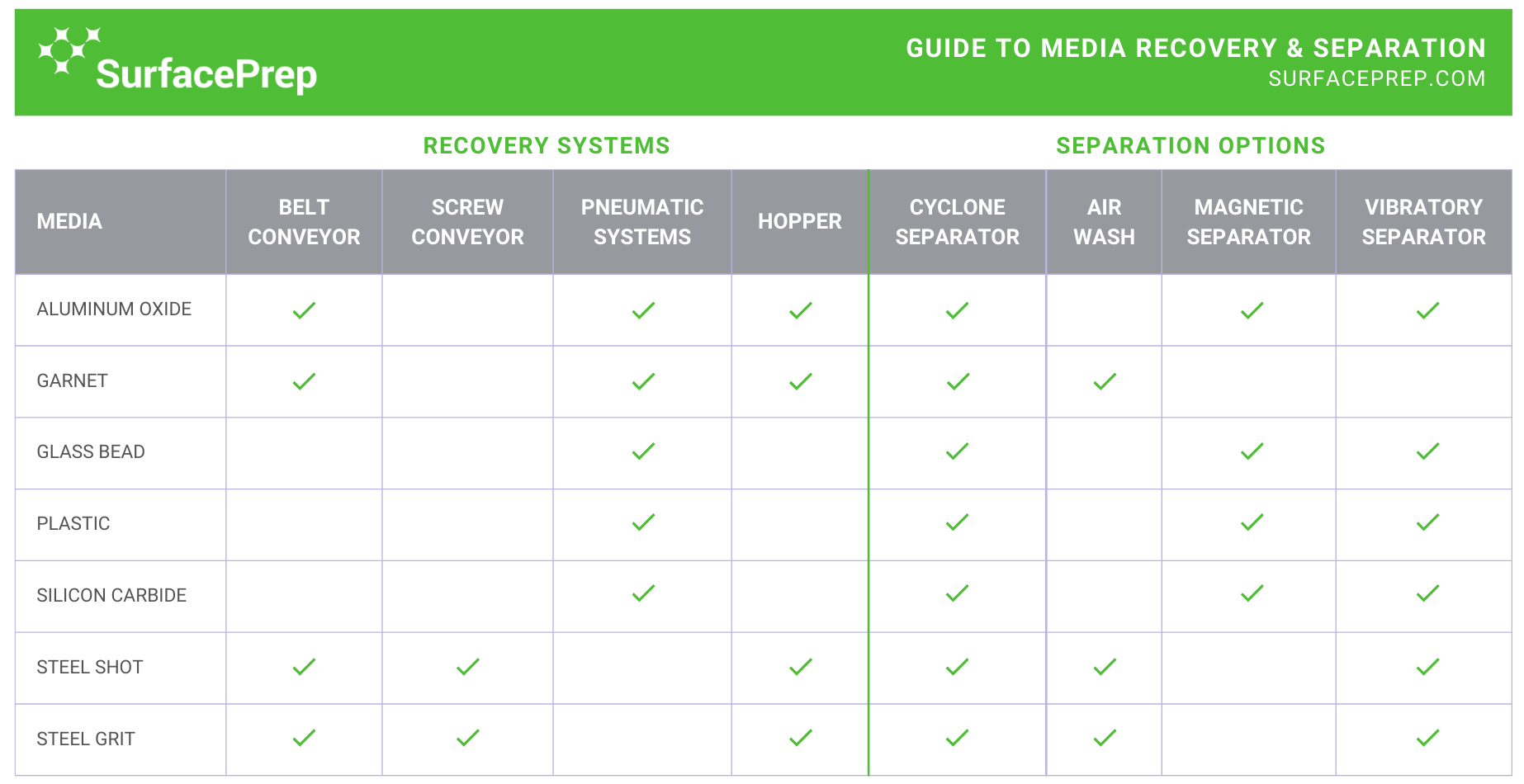

Recovery Systems and Media

The media used in any air blasting application will affect the recovery system that is needed. Our air blasting specialists are ready to help you select the right recovery system to pair with the media you are currently using. Haven’t decided on the blast media for your application? We can help with that too! Contact us today!

SurfacePrep partners with trusted OEM Manufacturers to supply a full range of air blast rooms. Let us help you overcome the confusion and find the right solution for your blasting requirements.

Some of our OEM Partners Include:

Blast Room Gallery

Why Choose Our Blast Rooms?

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.