Manual Blast Cabinets

Choosing the right blast cabinet can be difficult, especially when trying to balance cost, versatility, and performance. With so many options available, it’s easy to get lost in the details.

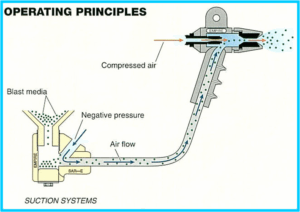

Manual blast cabinets come in two main configurations, each designed to address specific challenges:

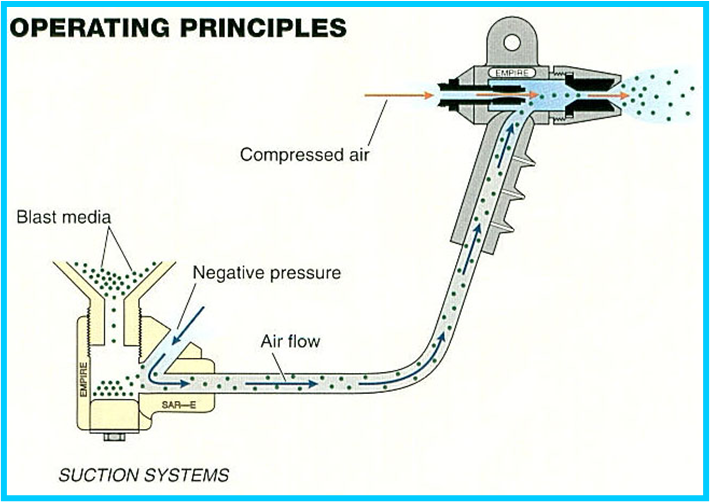

- Suction Blast Cabinets: Ideal for applications that require lower production rates, these cabinets use a venturi effect to pull abrasive material into the blast gun, mixing it with compressed air to blast the workpiece. Suction cabinets require lower air volume (cfm) compared to pressure blast cabinets.

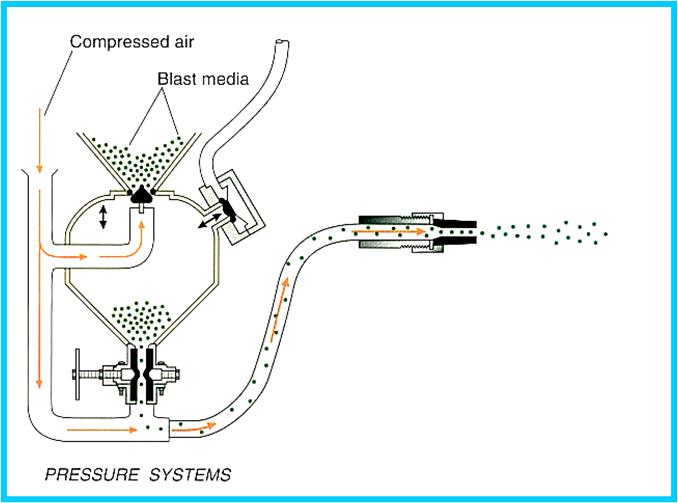

- Pressure Blast Cabinets: Ideal for applications that demand higher production rates, these systems use a pressurized vessel to contain the abrasive which is metered into the compressed air stream through a metering valve. The mixture is then sent under pressure to the nozzle to blast the workpiece. Pressure cabinets require more air volume (cfm) but can clean three to four times faster than suction cabinets.

Applications

Blast Cabinet Types

Blast Cabinet Accessories

SurfacePrep partners with trusted OEM Manufacturers to supply a full range of air blast cabinet systems. Let us help you overcome the confusion and find the right solution for your blasting requirements.

Some of our OEM Partners Include:

Why Choose Our Air Blast Equipment?

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

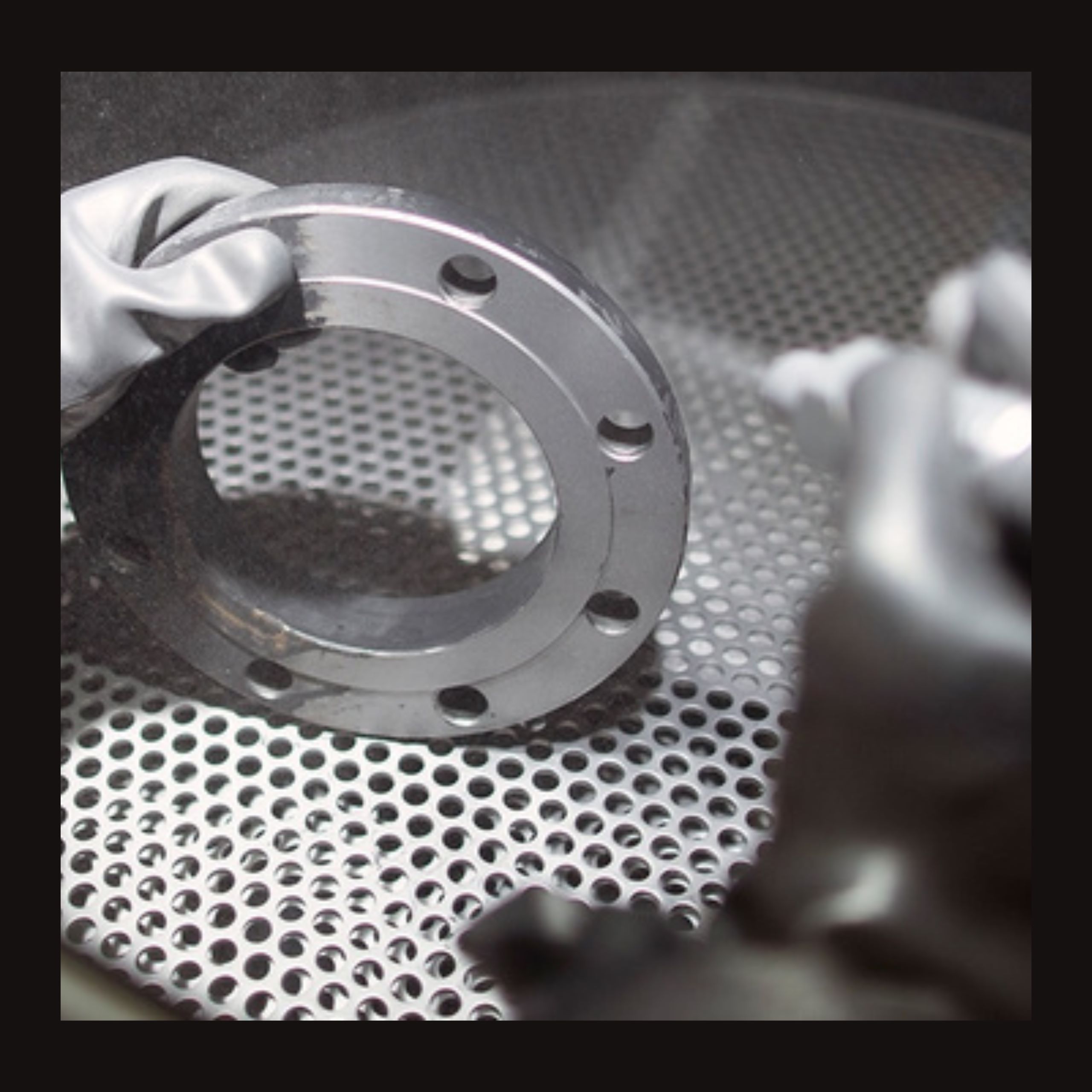

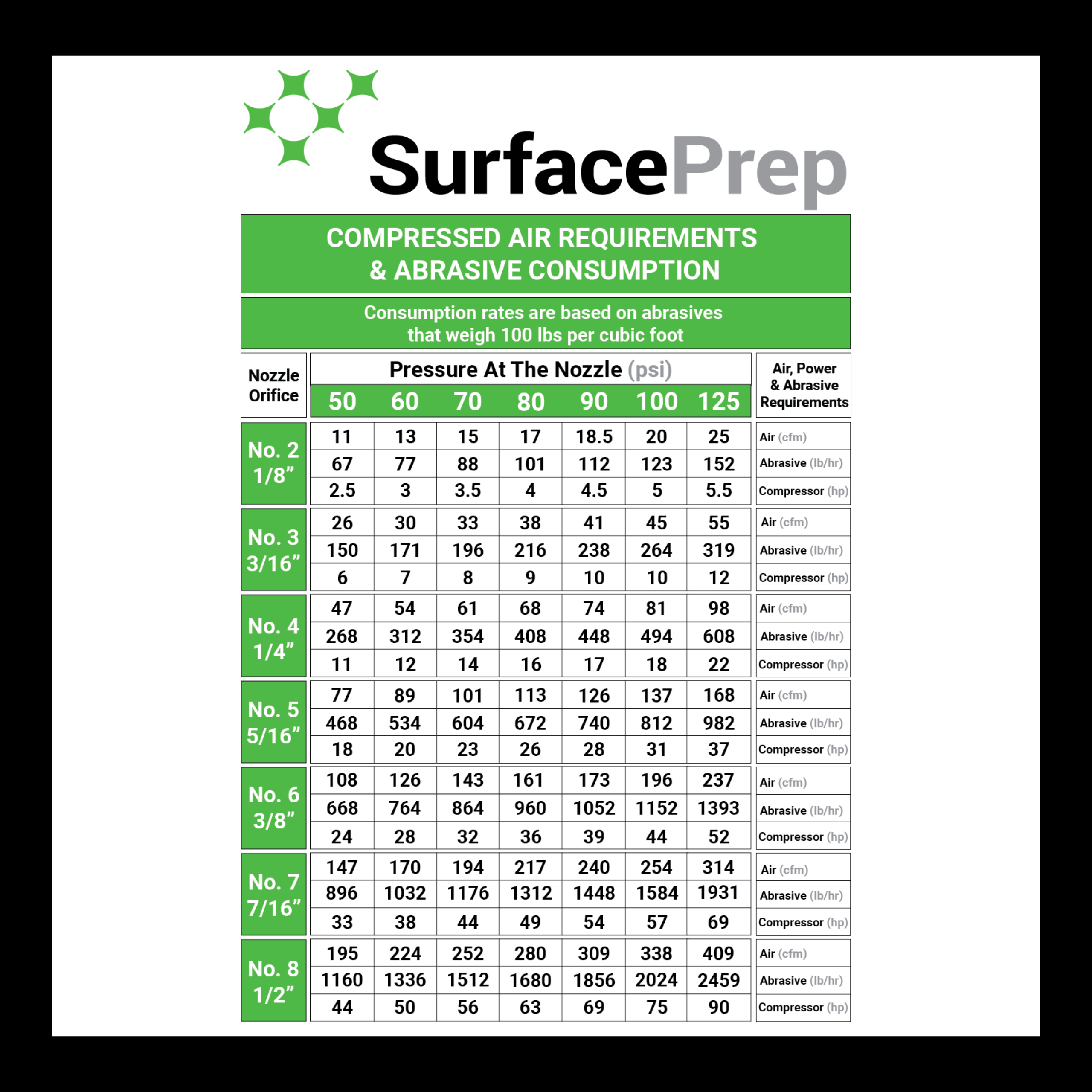

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.