Vapor Smoothing

Finishing Systems, You Can Trust

Finishing 3D printed parts can present challenges for manufacturing parts, especially for specific applications. Vapor smoothing reduces or eliminates the need for secondary finishing such as sanding, tumbling, and coating, by delivering final-use surface quality in a single automated cycle. Enclosed, fully automated vapor chambers with precise control of temperature, pressure and solvent flow delivers consistent smoothing cycles across entire build volumes. This allows the machines to handle high part throughput while maintaining dimensional tolerances.

SurfacePrep has partnered with AMT to provide machines that include a modular system design with small to medium build capacities available to suit each customer’s specific application. Their integrated solvent recovery and closed-loop filtration reduce facility requirements and eliminates external handling of chemicals. AMT’s PostPro line produces biocompatible, sealed surfaces suitable for ISO 10993 and USP Class VI testing for medical applications as well as aerospace and automotive certification. Their closed loop solvent management ensures compliance with environmental and worker safety regulations.

Speak to a SurfacePrep specialist today to learn about solutions for your specific application!

PostProSFX

PostProSF50

PostProSF100

Why Choose Our Vapor Smoothing Equipment?

Industry Articles

Comparing Suction and Pressure Manual Blast Cabinet Systems

Abrasive blasting is an essential process in the metal finishing industry, and choosing the right system can significantly improve your project's success.

The Importance of Proper Media Flow in an Abrasive Media Blast Cabinet

The right size of steel shot or grit blast media can make all the difference in a project's outcome. By understanding the application requirements and keeping in mind the equipment considerations, optimal results can be ensured.

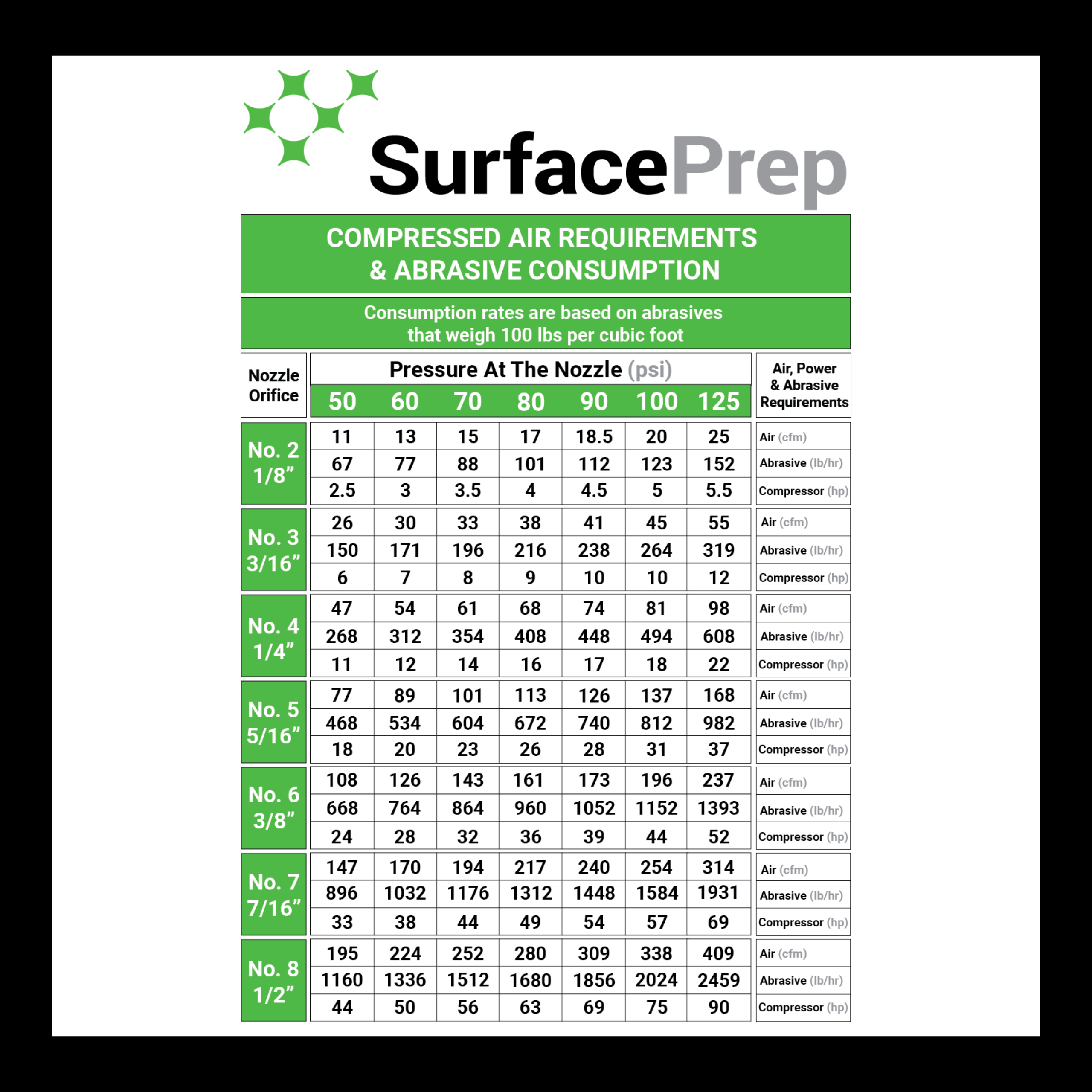

The Basics of Blast Nozzles: Factors to Improve Your Efficiency

The blast nozzle is the final exit point for high-speed abrasive particles in an air blast system and is a crucial component in achieving precise, efficient surface preparation.

Selecting The Proper Abrasive Blast Media

Choosing the right abrasive blast media is essential for achieving the desired finish on a variety of surface materials. The wrong choice can result in an unsatisfactory finish, wasted materials, and potential damage to the surface. As a leading supplier in the industry, SurfacePrep understands the importance of making the right choice. Here’s a guide to help you make an informed decision for your surface finishing application with commonly used abrasives.