Turning is an essential cutting tool application. In addition to a large selection of external and internal turning operations in all workpiece materials, SurfacePrep also provides several industry-leading technical solutions. This includes heavy turning, numerous railway applications, and several tube and pipe machining operations including scarfing and bar peeling.

Turning products available are often composed of these materials:

- MT-CVD (medium temperature chemical vapor deposition)

- PVD (physical vapor deposition)

- Ceramic

- Cermet

- CBN (cubic boron nitride)

- Diamond

SurfacePrep represents many major brands of turning cutting tools such as Sandvik, EMUGE, and more.

ISO Turning

The assortment of ISO turning inserts and tool holders is one of the widest. A variety of shapes, sizes and grades all deliver high levels of reliability across the full range of machined materials with unique carbide powders, coatings and advanced materials including PCD (polycrystalline diamond), CBN, and ceramic.

Parting & Grooving

This selection delivers stable cutting process for radial/axial, external/internal parting & grooving and copy turning with a width range from 0.035 inch (0.9mm) to 0.3 inch (8.0mm). A strong clamping system and optimized geometries and grades promote efficient chip formation and removal.

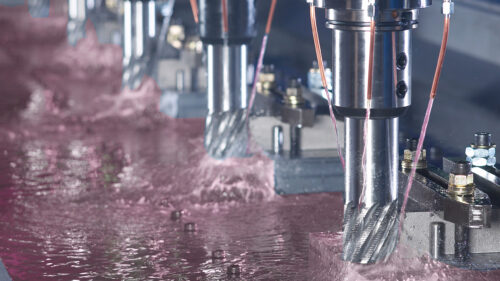

Scarfing

We offer a complete program of tool holders and inserts for scarfing – the process of removing the weld deposit created during tube production. The proprietary assortment of tool holders and inserts covers external scarfing as well as scarfing rings for internal operations in all common tube diameters.

Bar Peeling

We offer a specific assortment for bar diameter reduction and removal of defects from forgings and castings. This includes insert shapes, geometries and grades for steels, stainless steels and other difficult to machine materials. We also offer clamping systems and cassettes for process reliability, surface quality and durability of the cutting edge.

Thread Turning

Our wide assortment of turning tool-holders and inserts are to machine internal and external threads in various metric and inch thread profiles. This includes M, W, RD, API, TR, UN, BSPT, NPT, and ACME.