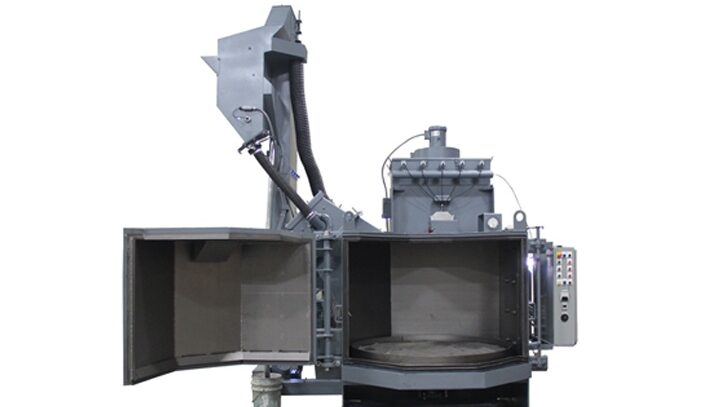

Table wheel blast machines consist of a table that rotates beneath a blast wheel, or series of blast wheels within a cabinet enclosure. Table machines process a batch at a time. Table wheel blast machines provide options to finish large parts weighing up to 10,000 pounds.

The rotating table helps expose the parts to the media stream. Table blast machines, depending on the diameter, will come with one to three wheels to provide coverage on the exposed surface. If full coverage is needed on the parts, they will need to be flipped over.

These machines are well suited for parts that are fragile and part-on-part impingement is unacceptable. Table systems are good candidates for parts that are sensitive or not suitable for tumbling. Standard table blast machines range from 48″ diameter table size up to 84″. Table wheel blast models bigger than 84″ diameter are available should your process require a larger machine.

Crane slots are available as an option to help facilitate safe loading and unloading.