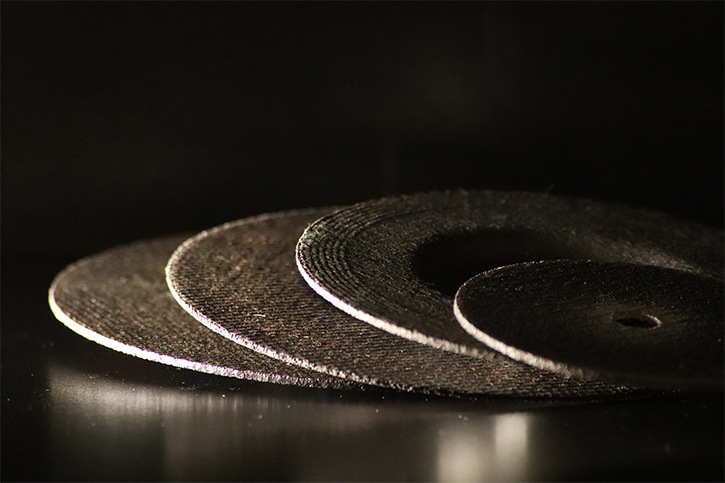

Common Bonded Products:

- Grinding Segments

- Grinding Wheels

- Cut-Off Wheels

- Chop Saw Blades

- Cones

- Plugs

- Mounted points

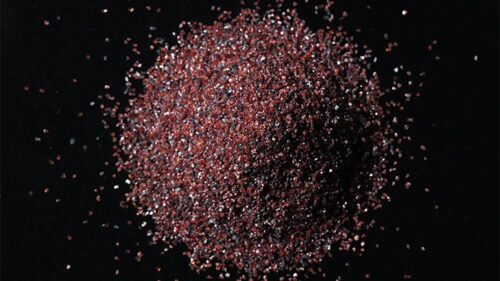

Most Common Grains Available:

- Aluminum Oxide

- Zirconia

- Ceramic

- Silicon Carbide

- Diamond

- cBN

- Combination Grains

Diamond and CBN products are available in resin or electroplated bonds.

Vitrified Wheels and Segments are used in tool rooms with production surface grinders or centerless machines.

Technical Information:

Bonded abrasives are available in coarse to fine grades. Bonded abrasives are used for stock removal, grinding, weld blending, cutting, beveling, sharpening, and precision finishing. Bonded abrasives come in a variety of grains, grit sizes, bonding compositions, shapes, and sizes to fit many applications.

Bonded Abrasives are a mixture of abrasive grains, fillers, and bonding materials. The bonding agents can be resin, rubber, glass, or other materials. As the wheel spins against the surface of a work piece, the grains fracture and wear away. As the top layer wears, a new layer of grains is exposed.

SurfacePrep is proud to represent all major brands of bonded abrasive products, including 3M, Norton, CGW Abrasives, Falcon Abrasives, Allison Abrasives, Radiac Abrasives, and many more.

Throughout the industry, many developments have been made using new types of abrasive grain and bonds to increase the performance. Each product is designed to give a specific finish, speed of cutting, and stock removal or cutting requirements.

The bonding compositions determine working characteristics. Softer bonds are referred to as fast cut, due to wear rates that quickly expose new grains. Harder bonds are called long life, making the wheels more durable. In tool room applications, the porosity of wheels can help carry coolant to the workpiece, reducing heat and loading. Contamination-free bonds are available for stainless steel applications.

Resin-bonded products are used for a wide range of applications, ranging from the tool room, foundry floor, or the job site.